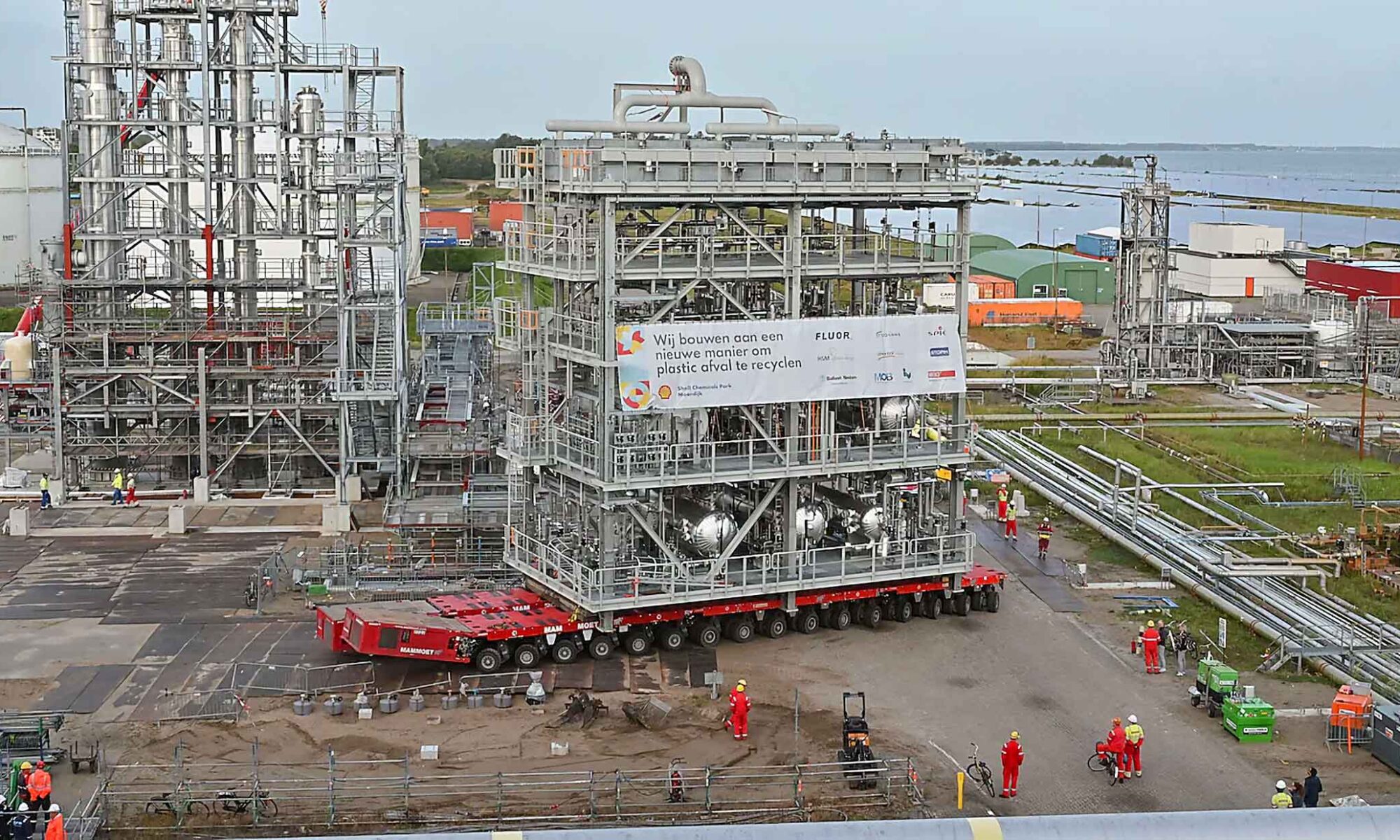

A month ago, this component arrived from HSM Offshore Energy. Transporting the 278-tonne unit across the Shell site took place using what is known as a Self Propelled Modular Transporter, a kind of modular heavy-duty giant truck, from the Dutch specialist company Mammoet.

The prefabricated unit and steel structure on the site now fit together seamlessly. The next few months will see hard work on wiring and installation of all piping.

Bionaphta

The upgrader plant aims to make pyrolysis oil, made from waste plastics, suitable as feedstock for the current naphtha crackers. This will allow new plastics to be made from it. The technology for the upgrader comes from BlueAlp, with which Shell entered into a joint venture last year.

The plant should be operational by 2024 and has a capacity of 50kton. “With this, the Netherlands can become one of the leaders in this transition,” Shell’s Paul de Hoog said at the Chemical Recycling Summit of the Network Chemical Recycling/Circular Biobased Delta late last year. Shell’s ambition is to process one million tonnes of plastic waste per year in its chemical plants worldwide by 2025 at the latest.

See also:

- The right time for chemical recycling is now (article, Agro&Chemistry, 29 November 2022)

- Shell to build plant for upgrading pyrolysis oil to bio-naphta (News release, Agro&Chemistry 2 December 2021)

Image: Shell Netherlands