Algae are the basis of several food chains. They contain proteins, minerals, vitamins, lipids, polysaccharides, pigments and phytohormones. Their composition is so diverse that they are suitable for a wide range of applications, from biofuels and biomaterials, to bioplastics; and from fertilisers or wastewater treatment to cosmetics, food, animal feed and even pharmaceuticals. Because they are as easy to grow as agricultural crops, but use little water and land, they are extremely efficient. Moreover, they absorb CO2.

Tiago Guerra, CEO of Portuguese start-up Algikey, believes that algae is a solution to many problems and would like to see its production industrialised. Algikey makes the selection and commercialization of microalgae and algae products, from biomass to the final product, streamlining the connection between producers and buyers.

Guerra identifies several trends. For instance, algae are increasingly used in the food and feed industry with the aim of replacing current raw materials with alternatives that are sustainable, renewable and safe, but also offer better properties for the development of entirely new products. “Think of the replacement of soya proteins. Algae can consist of up to 60% protein and contain many (essential) amino acids. They can replace fish oil as a vegan source of Omega-3 fatty acids that also reduces the pressure on ‘wild’ fisheries. DHA algal oil is already widely available and accepted. In fact, demand for EPA from algae currently exceeds supply. Algae oil can also be an alternative to the widely used palm oil and thus help to reduce deforestation.”

Many benefits

There are many benefits of using algal biomass in feed and food: they improve livestock welfare, reduce methane emissions, enable the production of vegan meat and fish flavours and can be used as natural colourants. “However, there are also limitations, such as the GRAS and the Novel Foods legislation in the US and Europe, the still relatively small scale of production and the relatively high prices that go with it, which restrict their use to specialty feeds and foods.”

Broad applications for algae can also be found in the nutraceutical and nutricosmetic industries, such as vitamin and mineral supplements and antioxidants. They are aimed at improving the well-being of the end customer, who can use them for muscle recovery, weight loss, digestive support and immune response.

“Industrial cosmetic companies also use algae because they are looking for natural, sustainably produced, high-quality molecules and pigments for spa treatments, skincare products with improved UV protection and for skin firmness and softness, in addition to natural colours for makeup. Pharmaceutical companies are particularly interested in algae as a new industrial source of natural molecules that can be used in the development and application of medicines.”

Water treatment

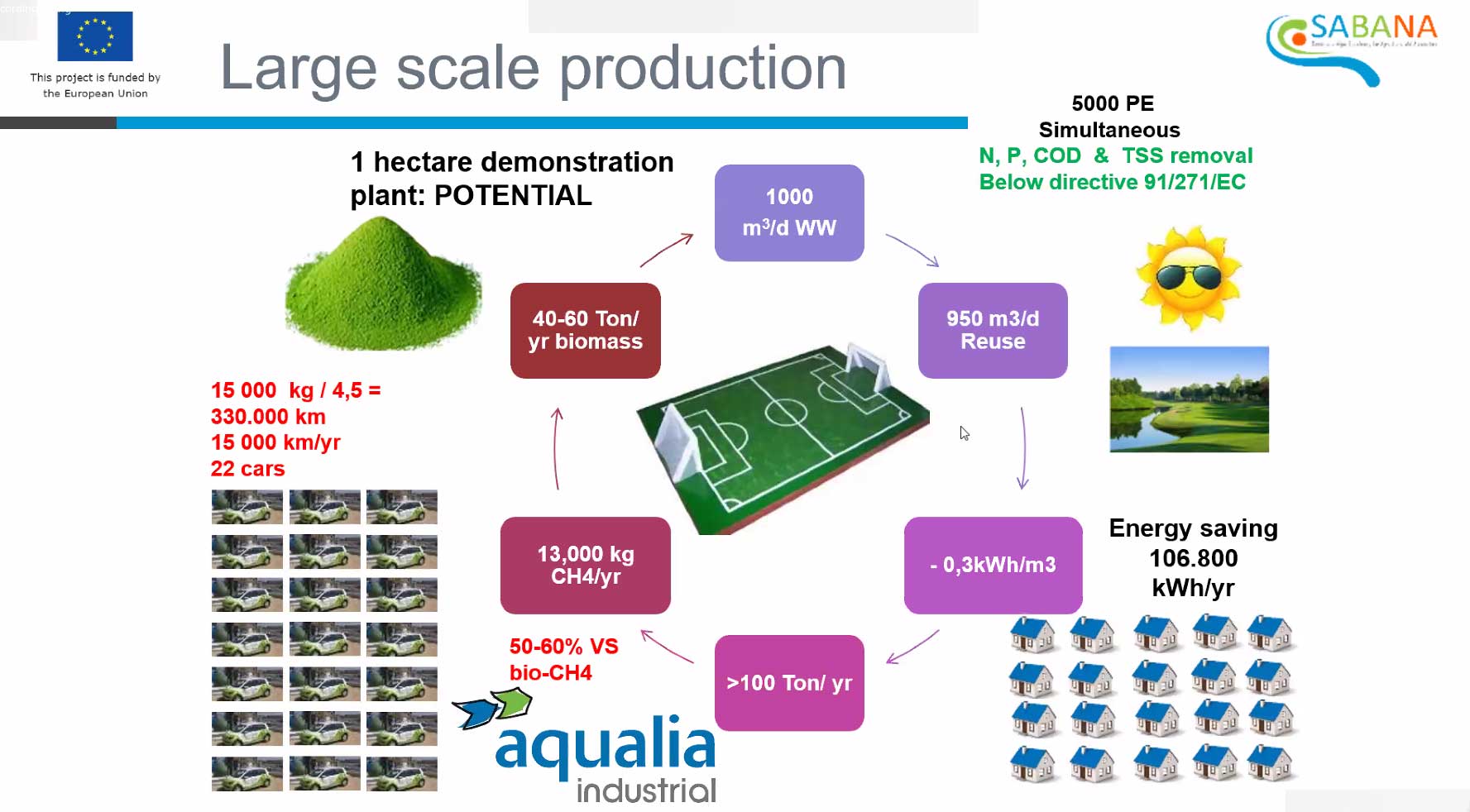

An entirely different trend is the use of algae for (waste) water treatment. From a circular economy perspective, this is important because it enables, for example, fertiliser producers to recover nutrients such as nitrogen and phosphorus from water, with low CO2 emissions. Water recycling companies can also use algae to clean water in a sustainable and energy-efficient way, with the algae breaking down CO2 from the surrounding industry. Besides clean water, side streams such as biofuels and fertilisers become available. This can make the construction of large production facilities very profitable, said Gabriel Acien. He is a professor of chemical engineering at the University of Almeria in Spain and vice president of the European Algae Biomass Association (EABA). In the SABANA project he worked on the recovery of nutrients from wastewater using microalgae.

SABANA stands for Sustainable Algae Biorefinery for Agriculture aNd Aquaculture. It involves the development of a large-scale integrated microalgae-based biorefinery for the production of biostimulants, biopesticides and feed additives, in addition to biofertilizers and aquafeed, using only marine water and nutrients from wastewaters (sewage, centrate and pig manure).

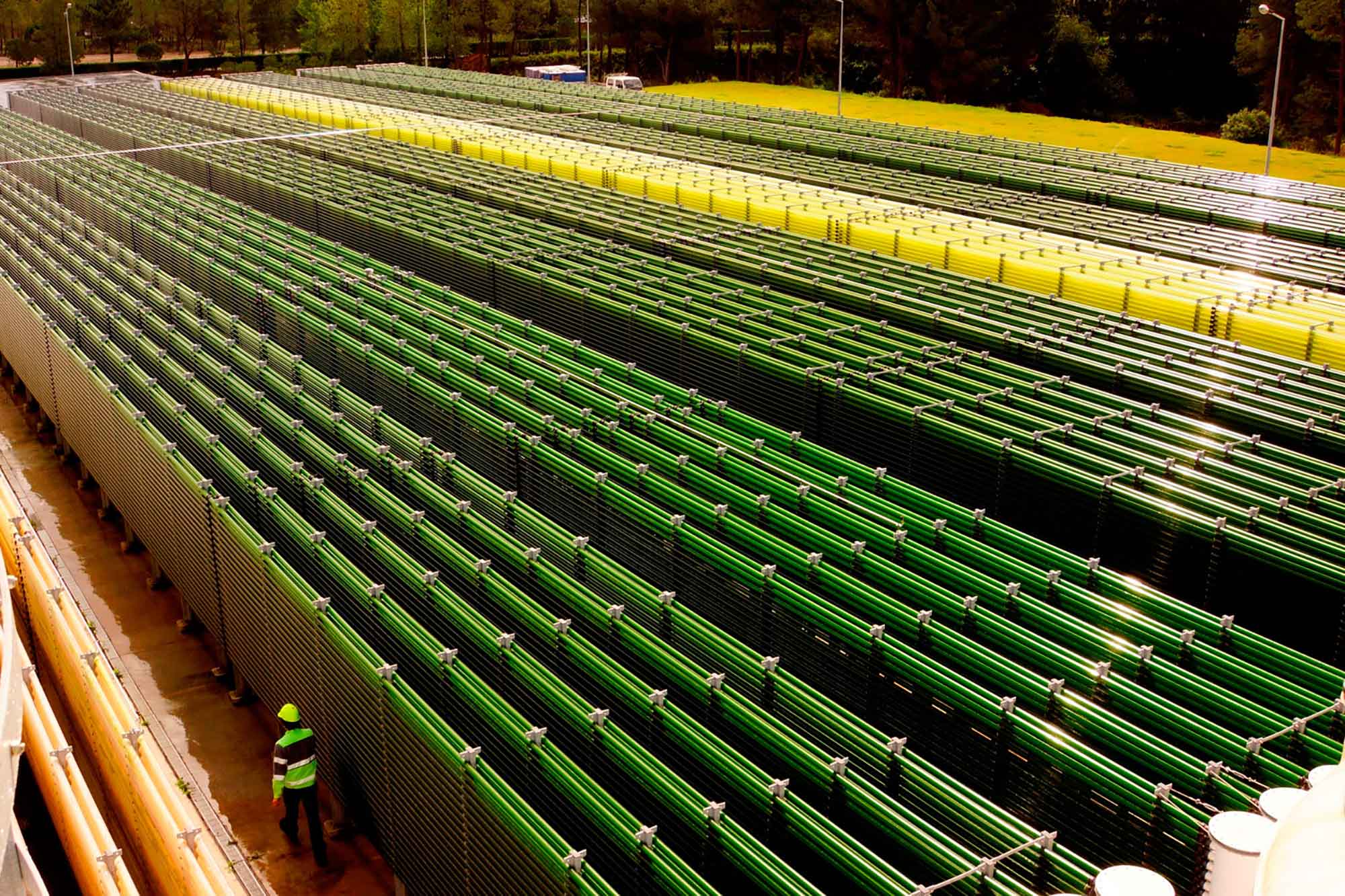

In a European consortium with ten partners from Spain, Germany, the Czech Republic, Italy and Hungary, research was carried out between 2016 and 2021. In total, 7 hectares of biorefinery facilities were realised. Professor Acien: “Our conclusion after four years is that we were able to demonstrate that it is possible to produce microalgae biomass in combination with water treatment. We also measured the performance of the produced biomass in field tests. We found that the system is stable throughout the year. It is able to cope with large fluctuations of temperatures and solar radiation. The quality of the biomass is excellent for use as a biostimulant in agriculture.”

Several tests in cooperation with farmers showed that the algae-based biostimulants had a positive effect on the root growth of plants, enabling them to better absorb nutrients. “This enables the farmer to use up to 20 percent less chemical fertiliser. At the same time, the plant’s tolerance to stress conditions improved and the plants were better able to bear more fruit even in the cooler winter periods. Moreover, the plants proved to be more resistant to pathogens. We are still investigating whether this is because biostimulants act as biopesticides, or whether they strengthen the immune system of the plants so that they can better protect themselves. Finally, we were pleased to be able to demonstrate that the system also works on a larger scale.”

Sustainable technology

Up to 1,000m3 of wastewater can be treated per day on a one-hectare site using this technology. Compared to conventional water treatment, this saves 106,800 kWh per year, enough to power 20 homes all year round. In addition, 13,000 kilos of biomethane are produced (enough to drive 22 cars 15,000 kilometres a year) and 40-60 tonnes of biomass. Acien: “By any measure, it is a sustainable technology. We are demonstrating that it works in real-scale facilities, in real towns, not under the supervision of scientists, but with ordinary people.”

Now that this circular concept has been proven in practice, the remaining bottleneck is regulations. These do not allow the use of biomass grown on wastewater to grow food crops. “We have measured the levels of pathogens, heavy metals and so on in the algae biomass,” says Acien. “They are low and comparable to other substances that are permitted to be used in agriculture. We need to encourage the development of such commercial applications and urge the European Commission to amend the regulations on them.”

Greener materials

Sustainability regulations are one of the drivers for the initiators of the BBI-funded Multi-Str3am demonstration project to develop a concept for producing greener materials. Alternatives must be sought for microplastics or substances that are harmful to the environment, for example. Consumers are also asking for this.

The industry must therefore look for new raw materials and building blocks for more sustainable products. This offers opportunities for algae biomass, yet this source remains underused. “This is mainly because algae biomass is not yet available on a commodity scale and is therefore relatively expensive for the time being,” explains Luis Costa of Algae4Future (A4F), one of the eight consortium partners in the project.

“The Multi-Str3am project aims to remove the barriers. Firstly, by improving multiple strains of algae to increase productivity and better match the demands of end users. Then, we will look at improving the efficiency of cultivation and harvesting technologies, the opportunities for using side streams from industry (and our own production) during cultivation, combining technologies and valorising all fractions of the biomass (a zero waste approach).” The result should be a sustainable, multi-strain, multi-method and multi-product microalgae biorefinery that integrates industrial side streams to make high value products for food, feed and fragrance.

By now, the project has delivered a number of extracts containing carotenoids, Omega-3 fatty acids, proteins and the blue pigment phycocyanin. A regulatory mapping focusing on food, feed and fragrances has also been delivered. Furthermore, a life cycle assessment (LCA) and the development of communication tools are being worked on. Ultimately, all this should lead to alternative, sustainable products that can be produced by industries in the EU, using sidestreams, less waste, fewer emissions and less land and water use.

Competition

The question remains whether competition will arise between biomass for food and biomass for materials when using algae biomass. Gabriel Acien does not think so: “The production of one kilogram of algae high-quality biomass for food applications currently costs between 5 and 20 euros. In order to penetrate the market for biomaterials, the cost price has to drop below 1 euro per kilo.” Luis Costa adds: “No competition is created, on the contrary. Algae biomass can grow on marginal land, and there are many of those in Europe. These are lands where no agricultural crops grow now. Thanks to algae production, we can grow proteins and vegetables that would be impossible to grow in these places with conventional agriculture.”

See also:

- “The most sustainable biomass comes from the sea” (article, Agro&Chemistry, 31 March 2022)

This article was produced in collaboration with the Bio-based industries Consortium.

Image above: Ye.Maltsev/Shutterstock