This study programme is a good example of a multidisciplinary way of working that furthermore is also border-transcending,” says Jan Hans, Project Coordinator and Lecturer at NHL Stenden. “You are dealing with cultural aspects, not just between Dutch and German students, but also between Mechanical Engineering and Life Science students, for example. Dutch and German students work together on an assignment in which they are tasked to replace a single-use plastic with a sustainable alternative. In other words, this not only involves bio-polymers, but the circular economy as a whole.”

“This border-transcending partnership with NHL Stenden in the field of plastics technology came about as a result of the ‘Biobased Economy – Green Chemistry’ project,” says Wolfgang Arens-Fischer, Professor at the Lingen campus of the Osnabrück University of Applied Sciences. “In the future, German and Dutch entrepreneurs that are not enrolled at the university will be able to participate in some of our courses free of charge.” In any event, the university maintains close contacts with companies in the region, since students, in the context of the dual study programme, will be trained in companies. What they learn in their studies will therefore directly flow back to the regional economy in the form of information.

Greater flexibility

In addition, Dutch and German students also get to know each other and become aware of the differences in how education is structured in each country. For example, German students will follow a dual study programme in which learning is alternated with working in a company, in this case the energy company E-ON. Jessica Herzig: “This means that we can immediately put into practice what we have learned; for example in designing electric vehicle charging stations made of biodegradable bio-plastics. However, in this dual study programme everything is fixed and everything is prescribed. There isn’t a great deal of flexibility. From what I can see, there is more flexibility on the Dutch side.”

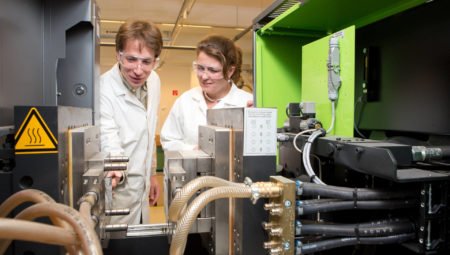

Rudy Folkersma, Lector and Project Manager at NHL Stenden concurs: “In the Netherlands, we primarily use a practice and application-oriented approach, if possible in specific pilot projects. The corona crisis often throws a wrench in the works in this regard. We as much as possible try to continue practical lessons in our laboratories, but lectures are primarily held online. Out of necessity, the so-called ‘poster pitches’ at the end of a course are also conducted in a virtual environment. In previous years this was more of a festive occasion, with invited guests.”

Close to reality

While learning using Zoom has its drawbacks, many students in Lingen nevertheless chose to enrol in this course. Herzig: “During our studies we had a choice of plastics technology or construction technology. Most students chose plastics technology because meeting students from another country is of course interesting, but also because the teachers have created an exciting programme that is very close to reality.”

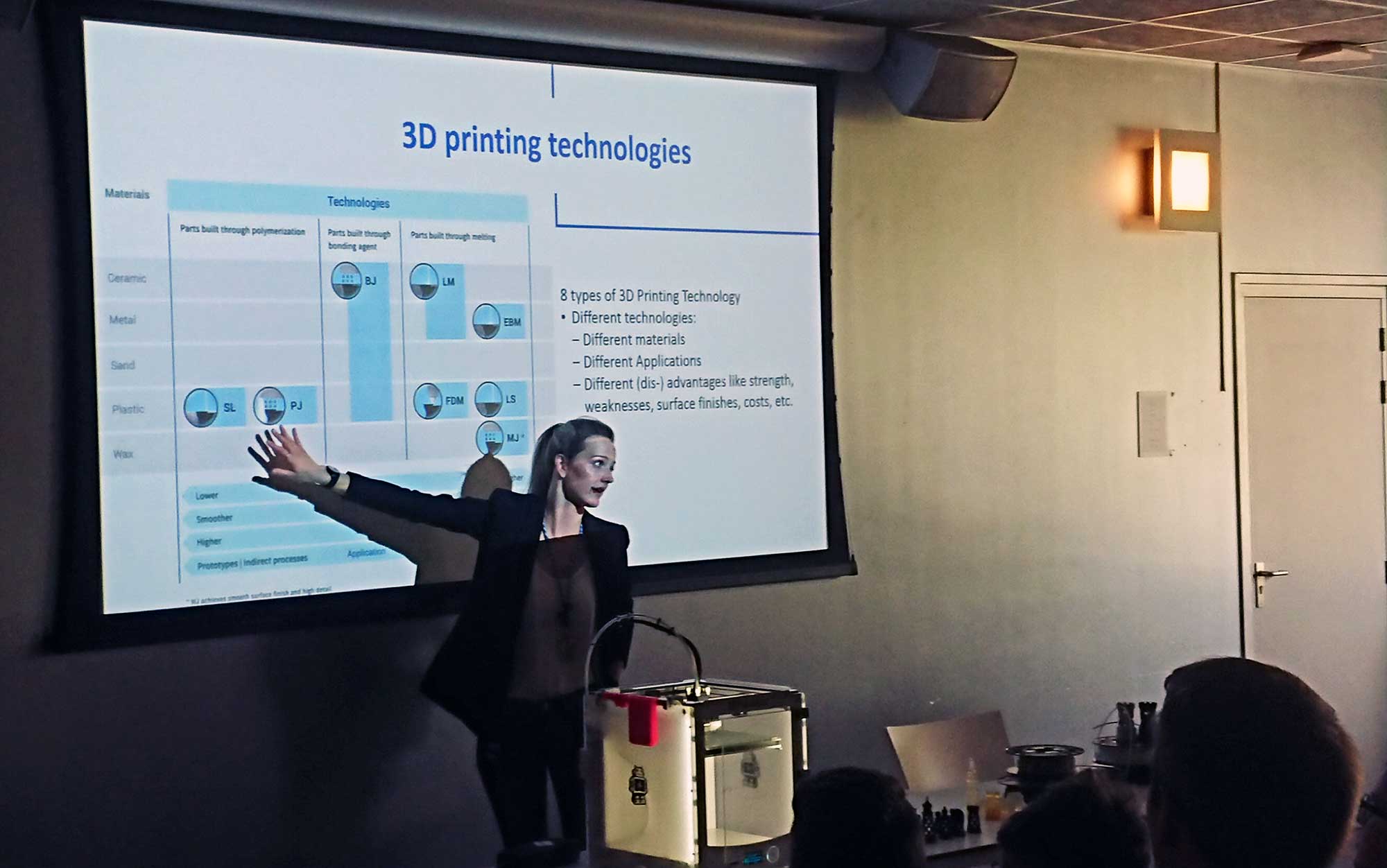

This programme deals with many aspects of sustainable plastics technology, ranging from the production of bio-polymers to processing in a plant, and from self-healing ‘smart’ materials to recycling.

“I especially liked the emphasis on recycling and sustainability,” says Jessica Herzig. “It was also easy to follow for students who are not as deeply immersed in chemistry and have less background knowledge of this subject matter.”

The study programme’s versatility was one of the reasons why Mika Schröder enrolled in this course. “I like to acquire a broad view and ensure that I absorb something from different fields of endeavour in my studies. I am therefore very positive about this course and highly recommend it. It has given me insight into the current state of affairs in the field of bio-polymers, a theme that will become increasingly more important in the future.”

Continued education

“The nice thing is that the students enrolled in this course are introduced to topics they can continue to study later within the lectorate,” says Rudy Folkersma. “I hope that in their third or fourth year they will then take a minor or complete a graduation project with a company in this field of study.”

It is also possible to enrol in a master’s study programme in the field of bio-polymers, jointly set up by NHL Stenden and Windesheim University of Applied Sciences in Zwolle in the Netherlands. “We are going to investigate whether it is possible to exchange the modules of this master’s degree with the Industrial Engineering and Management study programme of the Hochschule Osnabrück in Lingen. We are still in the process of discussing this possibility.”

In addition, a start was made on creating a further training programme at the senior secondary vocational education (MBO) level for people who are already working in the plastics industry. Jan Hans: “In Emmen, together with Drenthe College, we developed a course in the field of plastics processing. We would like to do something similar with Lingen in Germany, as well. This is already very concrete: a network of German plastics processing companies is involved and market research has been completed.”

This article was created in cooperation with the Biobased Economy Project Team of the Eems Dollard Region (EDR).

Image above: NHL Stenden