PVC or polyvinyl chloride is the third most widely used plastic in the world, after PE and PP. About 100 million tonnes of ‘virgin’ fossil PVC are produced every year, which is about 18% of all plastics worldwide. It is found in pipes, window frames, cables and floor coverings, among others. Yet only 1% of all PVC is currently recycled (for comparison, for PE this is 20%).

‘World’s most dangerous polymer’

PVC recycling is hampered by impurities such as PE, rubbers and metals. For example, old PVC often contains lead as a stabiliser, which is no longer permitted today. Furthermore, there are toxic plasticisers in PVC products, known as phthalates. Separating the individual components of PVC using the traditional method requires organic (toxic) solvents as well as heating the PVC.

When heated above 150 degrees Celsius, however, hydrochloric acid (HCl) is emitted. This is highly caustic, highly corrosive and therefore destroys the recycling equipment. Moreover, in case of fire, highly toxic dioxins can be released into the atmosphere, as happened in Italy in 1976 in the infamous Seveso disaster, which killed thousands of people. It prompted new EU legislation around harmful substances. “PVC is one of the most dangerous polymers in the world,” Picchioni concludes. “Using supercritical CO2 for extraction combined with extrusion solves all these problems at once.”

Ultimate green solvent

Most people know CO2 simply as a (greenhouse) gas. However, it is a molecule with very interesting properties. By heating and pressurising it, it can change to a supercritical state, between gas and liquid. In that state, it is ideal to use as a non-toxic solvent, in which chemicals dissolve in a mixture. So does PVC and the additives in it – even at temperatures well below 150 degrees. When the pressure drops, the CO2 evaporates completely and only the dissolved substances remain.

The principle has been used for decades to decaffeinate coffee beans. The pressure required for this (73 Bar) could only be achieved with heavy pumps. The high cost of these made working with supercritical CO2 unfeasible for smaller companies for a long time. However, since prices have dropped significantly and European regulations limit the use of environmentally harmful organic solvents, there are more enquiries from business about the possibilities of this technology.

In 2017, at Francesco Picchioni’s request, Klaas Zijlstra of ASQA Subsidies brought together a consortium of 15 companies and the RUG to jointly start exploring these possibilities in a Supercritical CO2 Knowledge Centre to be established. For this project, under the name Industrie 2030, the SNN and the Province of Groningen allocated €4 million.

Patented technology

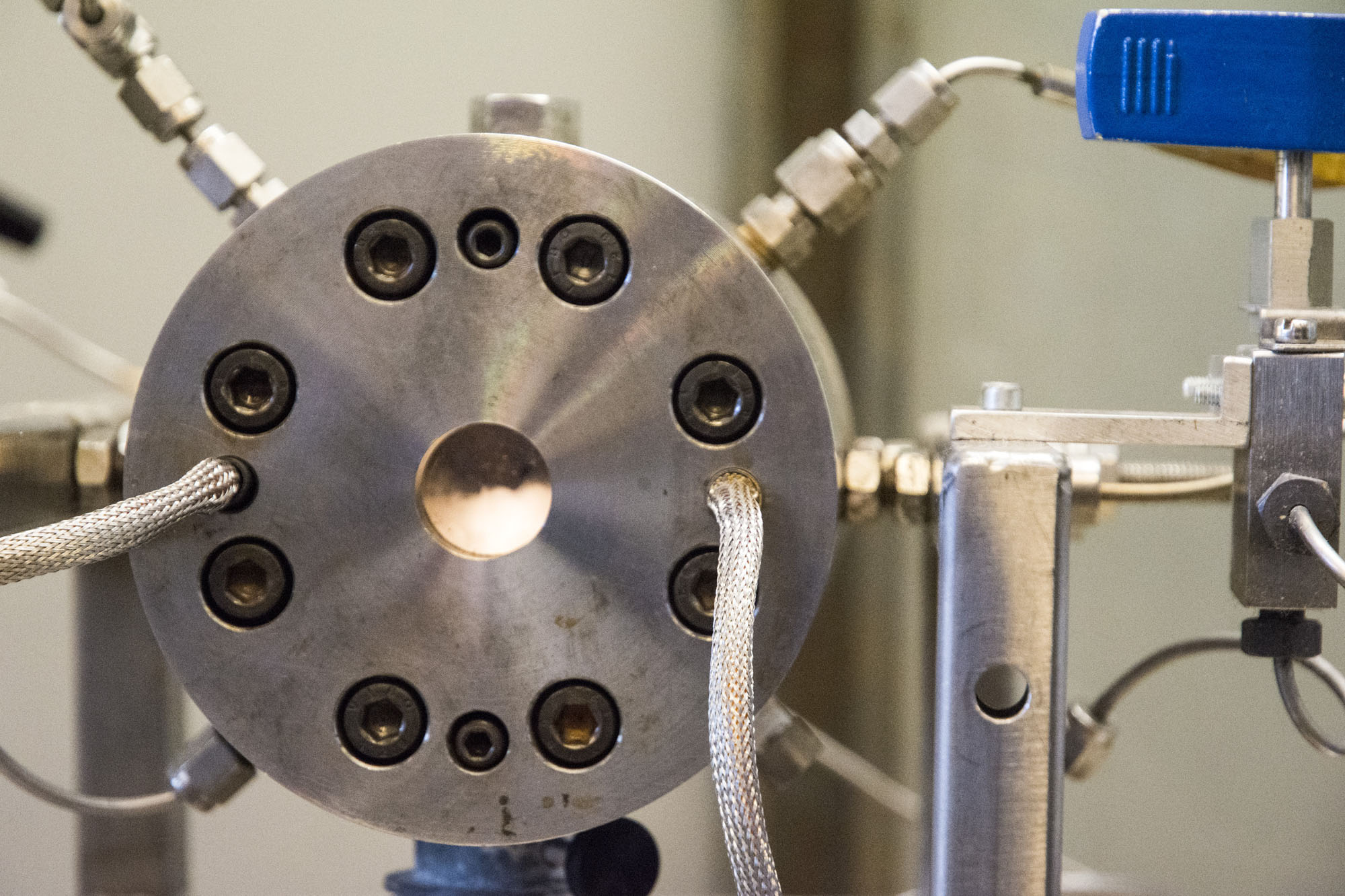

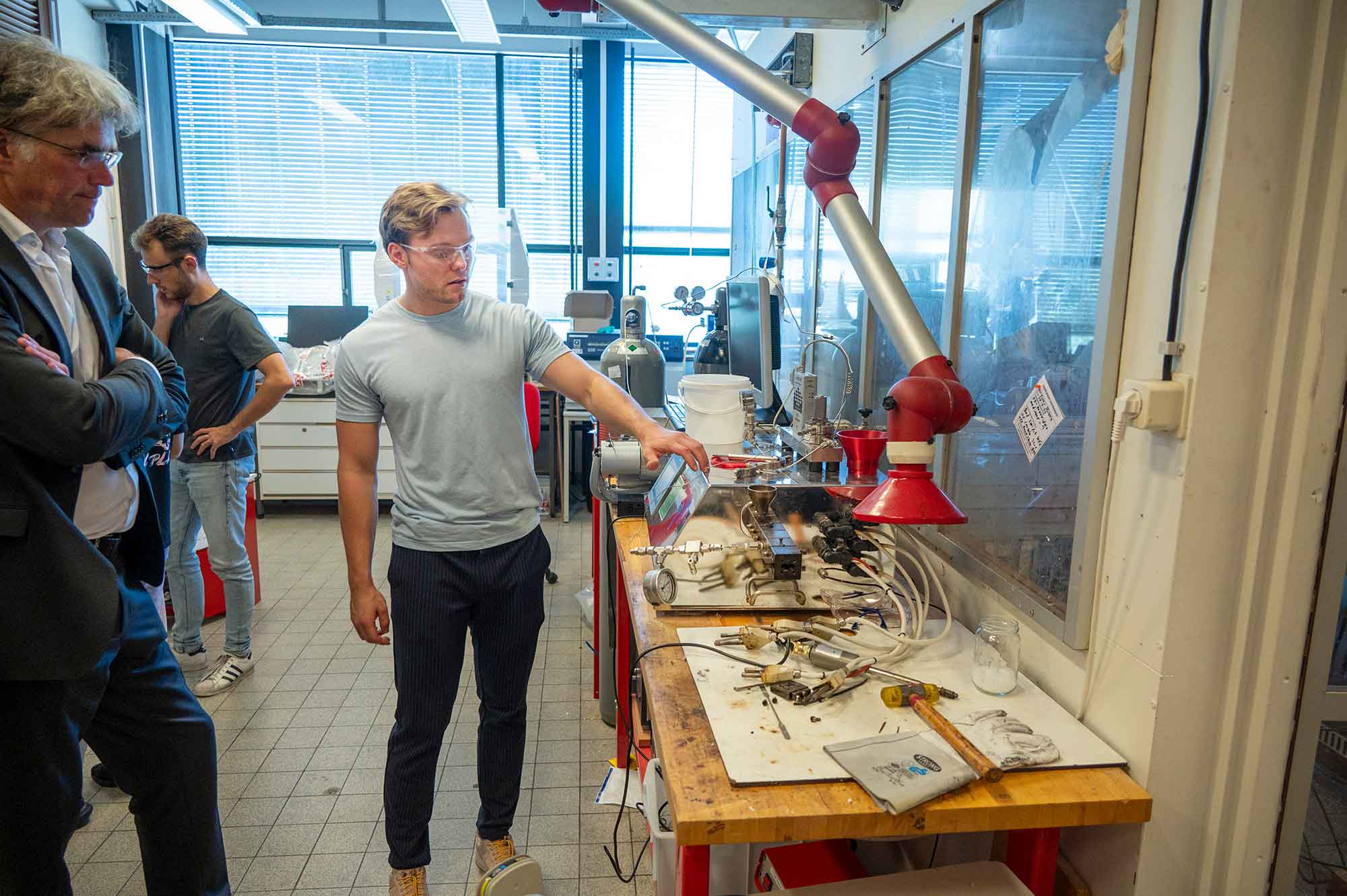

Hendrik Wolters, director/owner of TRH Recycling from Emmen, read about the initiative and got the idea to use supercritical CO2 to recycle PVC cable grinding material from telecom cables. With four students and the pilot plant in Professor Picchioni’s laboratory, that possibility was explored. It resulted in a promising proof of concept, which has recently been internationally patented.

The new upcycling technology combines various extraction methods, such as melt filtration, the use of scCO2 and extrusion. This makes it possible to separate PVC from both solids and plasticisers and other additives, including pollutants of very high concern (SVHCs, POPs).

The composition of PVC from waste streams can vary widely depending on the application. According to Picchioni, however, it makes little difference to the process whether sewage pipes, cables, or flooring are put into the reactor. “If the PVC is mixed with rubbers, metals or other polymers, we do have to adjust the extrusion accordingly, but that involves minor adjustments. The essence of the process remains the same.”

Expanding the consortium

Further development of the new upcycling method is hosted by the start-up Cescco2 BV, freely named after Picchioni’s first name. Together with consortium partners RUG, ASQA Subsidies, Prysmian Netherlands BV and Deepgrooves BV, the company will work on scaling up the technology – while continuing to look for new partners. Meanwhile, talks are also taking place with several international PVC manufacturers, including Japan’s Shin-Etsu Chemical; the world’s largest manufacturer by volume.

Groningen provincial executive member Henk Emmens (economy, agriculture and nature, among others) said he was happy with the JTF grant being awarded to the PVC recycling project: “This is exactly the kind of innovative project that suits the JTF. This European fund is designed to stimulate economic activity in regions disproportionately affected by the phasing out of fossil energy. In the northern Netherlands, it focuses on greenification and making SMEs and the chemical industry more sustainable, while preserving existing jobs and developing new ones.”

The JTF involves complex and large multi-million projects, in which companies collaborate with a knowledge institution. “That is why it is necessary to invest heavily in alliances of companies,” says Emmens. “It is just too big for an SME entrepreneur alone. Seeking cooperation is also precisely what knowledge and valorisation projects are all about. That is a huge exercise and you need to have specialists for that too. ASQA is one of those in the Northern Netherlands.”

Francesco Picchioni: “It is very nice to see that everyone is taking their role: one is from entrepreneurship, the other from science and the third brings the parties together and knows the way to subsidies.”

New recycling technology

Besides upcycling, the ‘PVC upcycling with supercritical CO2‘ project also includes developing new recycling technology. After all, there is a limit to upcycling. “We can give PVC a new life of maybe another 20 or 30 years after its 20- or 30-year lifetime, until a point is reached where the quality has become so low that upcycling again is no longer possible,” says Picchioni. “I hope we only reach that point after five steps, but it depends on the conditions in which the PVC has been used.”

Two technologies then come into play for the final end-of-life solution: conventional thermochemical recycling using a modified pyrolysis process, or biochemical recycling using enzymes. The latter is still in its infancy and is mainly a longer-term idea. Pyrolysis is already a common technology in which materials are heated to high temperatures under pressure and without oxygen. The RUG has developed a method to prevent HCl being released in the process, which will also be patented soon.

Next steps

The next step the consortium will take is to build a new lab-scale setup to investigate how best to scale up the upcycling technology with supercritical CO2. This phase will be completed by the end of summer 2024. After that, a pilot plant will be built in Groningen with a capacity of 200-300 kg per hour, which could be operational within one to two years.

According to René Langevoort, one of the initiators of Cescco2, this will also enable the first commercial production already. Eventually, the aim is to design upcycling lines with a capacity of around 1 tonne per hour thereafter, which can either be housed in existing PVC plants or stand-alone. “This has the potential to create a completely new industry,” he says.

The technology could very well be sold under licence for implementation elsewhere in the world. There is no need to fear that material flows will dry up. “All the PVC produced in the last 50 years is still roaming all over the world, because we don’t feel we can do anything with it. So there is plenty of PVC available.” Moreover, the technology of supercritical CO2 as a green solvent is not exclusively applicable to PVC, but also to other polymers and in other industrial sectors.

“This project can therefore serve as an example for others,” says Klaas Zijlstra. “We want to involve many more companies and together we will therefore actively look for new consortium partners and work on forming and building cooperation.”

Companies wishing to join the consortium or want more information first can contact Klaas Zijlstra of ASQA Subsidies or René Langevoort of Cescco2 B.V.

This article was produced in cooperation with ASQA Subsidies, University of Groningen and Cescco2 B.V.

Photo above: ltr Klaas Zijlstra, Henk Emmens, René Langevoort and Francesco Picchioni