A port area is the perfect location for chain integration, whereby the residual flows of one company are the raw materials for another. This is why Groningen Seaports focuses on closing the chain for the sustainable raw materials sectors that are present throughout the ports, ranging from building materials and electronic or household waste to the blades of the enormous wind turbines that after ten to fifteen years at sea have reached the end of their service life.

Circular Plastics proposition

‘The formation of a circular cluster around the offshore wind industry is consistent with the ambition of Groningen Seaports to safeguard chain integration,’ says CEO Cas König. ‘This is consistent with the Circular Plastics proposition developed under the Chemport Europe banner last year.’

Companies, the government and knowledge institutes work together here on closing the circular plastics chain, for example by facilitating companies focused on recycling wind turbine blades. Enerpy (radiolysis) and CfK Recycling (winner of the Sustainable Industry Challenge) developed innovative technology independently from each other designed to recycle the glass fibre composites used to manufacture the wind turbine blades.

Business Manager Circular Economy, Heleen van Wijk: ‘We note that the market is becoming highly innovative in this area. Composite recycling is a hot topic and is necessary for a circular energy transition. We are working together with market players, as well as knowledge institutes such as the University of Groningen (RUG) and the Netherlands Organization for Applied Scientific Research (TNO) on the latest innovations in this area.’

Connecting Factor

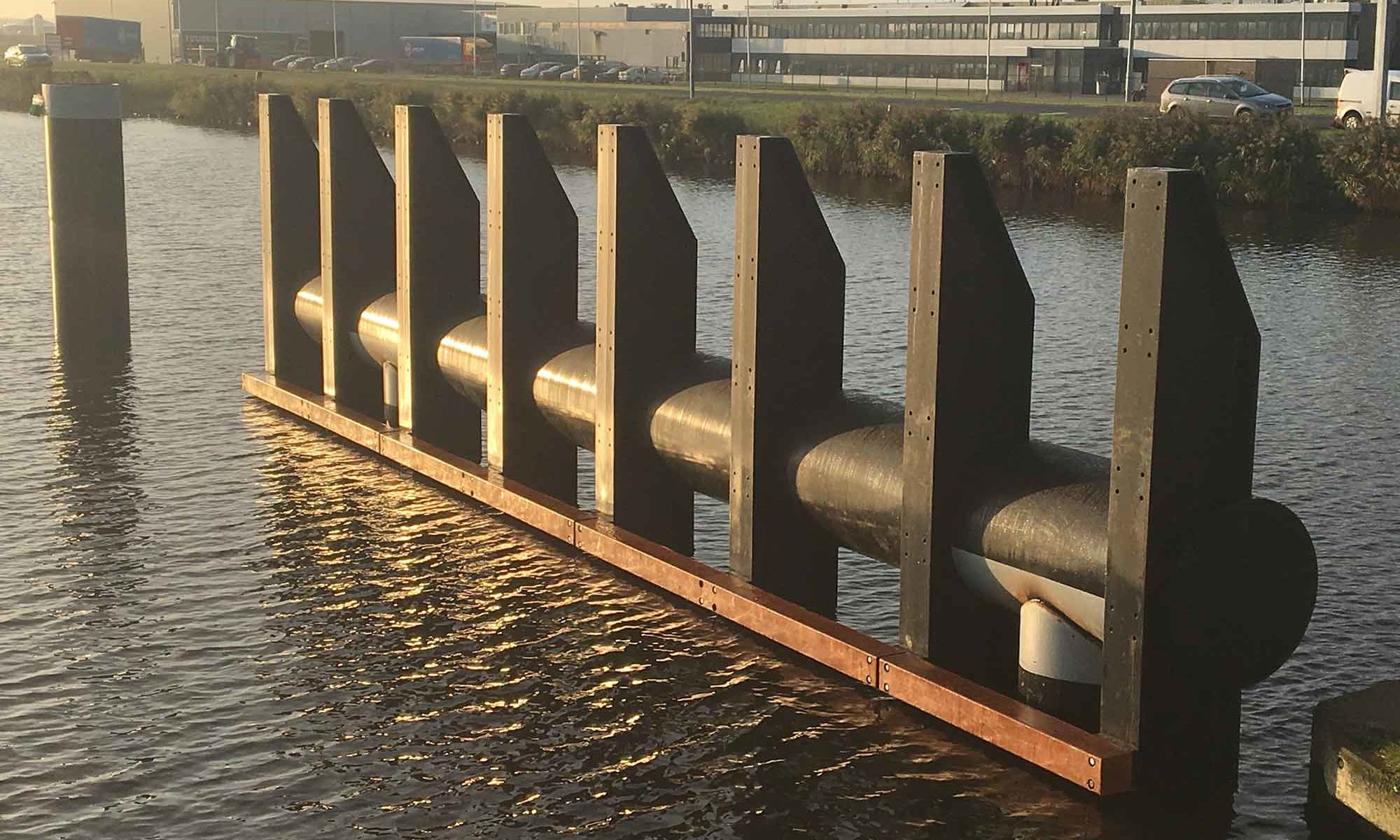

But Groningen Seaports is going beyond bringing parties into contact with each other. Companies in the port are actually working with recycled composites. For example, in 2019, the fenders of the Heemskes bridge in Delfzijl were made of recycled composites from wind turbine blades. In the meantime, a new project is underway.

‘To create a physical and instinctive separation between the Delfzijl industrial area and its surroundings, Groningen Seaports will be installing an earth wall with trees and plants all around the industrial terrain: the “Omzoming Oosterhorn” [Oosterhorn Perimeter] project. Various trenches will also be dug in this wall, for example to store the water coming from the industrial park. A landscaping plan has been developed in cooperation with landscape architects that provides for walking paths on and around the perimeter. Three pedestrian bridges made from recycled composite will be installed in cooperation with the local firm Heuvelman GSO. The bridges are currently being designed and they will be installed at the beginning of 2021,’ says Geert-Jan van Woggelum, Project Manager at Groningen Seaports.

‘In other words, Groningen Seaports is the connecting factor and the link that operates between the established order and new companies. We sincerely invite partners to contribute their ideas and to help further expand the value chain,’ says König.

This article was created in cooperation with Chemport Europe.

Image: Groningen Seaports