1. CHAPLIN: bio-asphalt

1. CHAPLIN: bio-asphalt

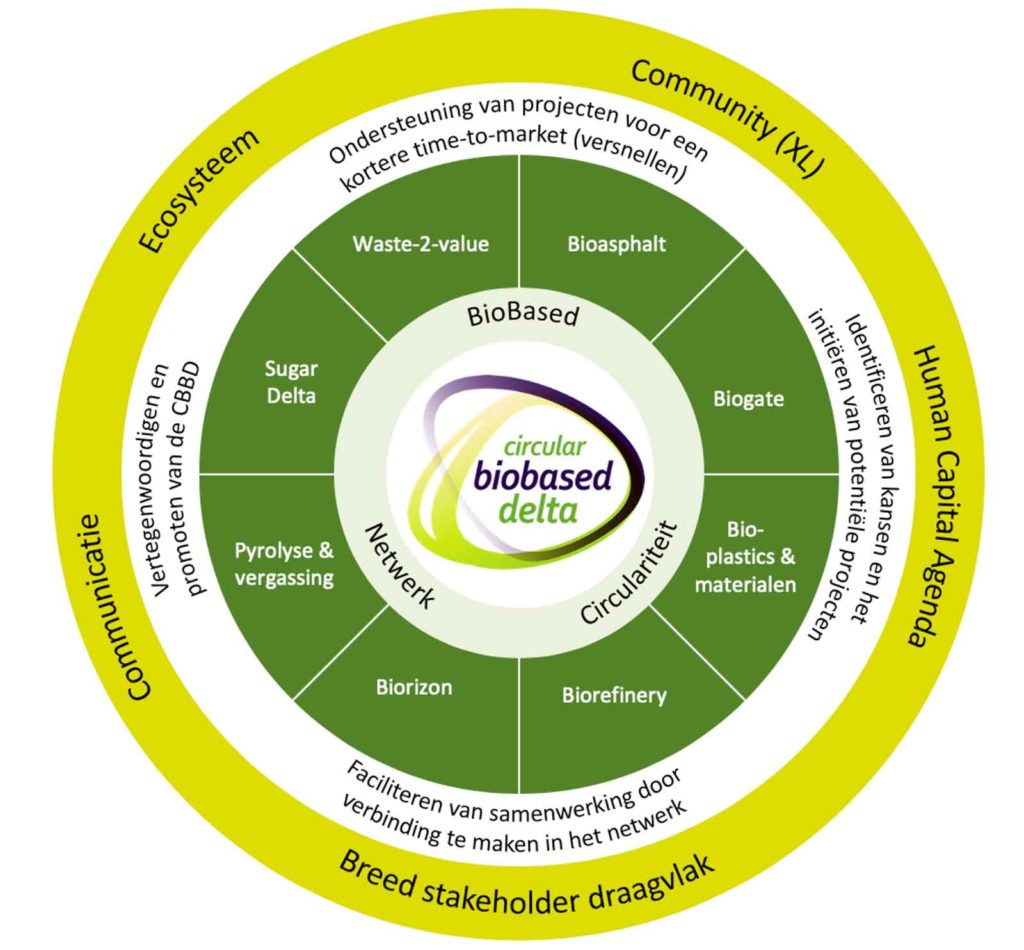

CHAPLIN focuses on making asphalt sustainable by (partially) replacing bitumen with lignin: a natural plant-based adhesive. The road construction sector is highly interested in this development. All of the required links in the lignin value chain up to and including the asphalt roads, as well as relevant knowledge parties, are represented in CHAPLIN. The priorities for 2021 (and beyond) include upscaling two existing projects, determining the properties and benefits of lignin asphalt and the formation of an international (European) consortium. In addition, preparations will be made for the next period (starting in 2022) and for communications to promote the transition to lignin asphalt.

2. Biogate: bio-EO

2. Biogate: bio-EO

Biogate focuses on the conversion of sustainable ethanol to high-yield ethylene oxide (bio-EO). Bio-EO is used in the PU market (soft foam for mattresses and furniture, automotive), surfactants, detergents, antifreeze and PET plastic. The initial feasibility study and the lifecycle analysis (LCA) have since been completed with promising results. This project alone produces 10% of the required CO2 reduction. Work can now be started on developing a business case. The formation of a consortium also is an item on the 2021 agenda. CBBD, together with the engineering firm GI Dynamics in Waterland, is leading this project on behalf of industry partners.

3. Bioplastics & Bio-materials

3. Bioplastics & Bio-materials

The objective of this programme is to accelerate the market implementation and circular application of a number of specific bioplastics and materials, such as adhesives, surfactants, coatings, composites, sealants and textiles in various market segments. A number of specific projects are supported: upscaling PHA (bioplastics) production from treatment sludge, kitchen waste and industrial wastewater, various projects focused on producing new materials from waste flows (grass, waste wood, construction waste), whereby the Centre of Expertise Biobased Economyl works with SMEs in the Delta region.

4. Biorefinery: refineries in the region

4. Biorefinery: refineries in the region

Multiple bio-refineries will have to be constructed in the region in support of a growing biobased economy, for example for the production of bio-fuels, chemicals and lignin for local asphalt plants. The business cases are generally challenging. In 2021, CBBD will focus attention on supporting the realisation of BiondOil and RJ Bioenergy, the most advanced biorefinery initiatives. This will happen in coordination with provinces and investors, including regional development companies. In addition, work will be devoted to creating synergy with CHAPLIN and other programmes in the field of raw materials or intermediate and by-products, such as CO2 and green gas.

5. Biorizon: bio-aromatics

5. Biorizon: bio-aromatics

Biorizon is the most advanced and renowned research programme in the field of bio-aromatics in the world. Bio-aromatics add essential functionality to, for example, plastics, resins and coatings. They constitute a sustainable alternative to petrochemical products that are difficult to recycle, such as paint, adhesives and lubricants. Biorizon aims to facilitate the commercial production of bio-aromatics effective from 2025. CBBD supports Biorizon in various ways, for example by creating a new application centre in 2021 and with a partnership with the start-up RELEMENT. Also see the article on the Biorizon Annual Event.

6. Pyrolysis & Gasification

6. Pyrolysis & Gasification

Pyrolysis and gasification are promising technologies for processing plastic waste, biomass and mixed flows, such as household waste, into energy, energy carriers and chemicals. Green Chemistry Campusl and the Southern Netherlands Pyrolysis Testing Ground play an important role in this area. Plastic pyrolysis is currently being embraced by the major naphtha crackers in the Southern Netherlands (Dow, Sabic, Shell). Chemical recycling consortia are being created here that are going to be producing on a commercial scale. Support for the permit application process and financing are key in this regard. The gasification route appears to be promising for biomass. CBBD contributes by acting as a pivot between the agrofood sector and/or waste market, the chemical industry and the final destination. Also see the article on the future of pyrolysis.

7. Sugar Delta

7. Sugar Delta

Sugar Delta aims to economically strengthen the region by attracting new industries that use sugar as a raw material. Work is underway on a branding and communication programme for the region, whereby the joint profiling of the port of Rotterdam and Biotech Campus Delft is possible. CBBD supports the local development companies with substantive expertise in the field of technology, markets and players, and has contacts with Invest-NL concerning financing. The focus is on large companies (€100 – €200 million). At the present time 6 to 9 potential projects have been identified under this programme.

8. Waste-2-Value: waste as raw material

8. Waste-2-Value: waste as raw material

Under the Waste-2-Value banner, CBBD combines a number of initiatives designed to convert waste and biomass flows to raw materials for industry. Various (large) companies are presently active in this domain. The use of CO2 as a building block for the chemical industry, known as CCU, also forms part of this area of focus. CBBD supports multiple projects in the field of gasification, wet and dry pyrolysis and hydropyrolysis in combination with innovative separation technologies. This is a fairly new field of endeavour. In 2021, CBBD’s acceleration team, the A Team, will work on identifying the right priorities, evaluating opportunities and attracting activities.

More information

If you are interested in or have a project that fits into one of above-referenced programmes and are looking for support or cooperation, contact us by sending an e-mail to circular@biobaseddelta.nl. For more information about our programmes, projects and the ecosystem, visit the Circular Biobased Delta website.

This article was created in cooperation with Circular Biobased Delta.

Image: CHAPLIN XL