She started 35 years ago as a microbiology student at Hanze University (then HLO) and in recent years worked for the University of Groningen and Hanze University, among others. Janneke Krooneman was active, for example, in the BERNN project Circular Biopolymers Value Chains for PHA and Cellulose. In 2021, she delivered a feasibility study for the teaching assignment Bio-process Technology at the Hanzehogeschool. The conclusion: this discipline deserves its own research group and belongs at the heart of the Research Centre Biobased Economy, the Zernike Advanced Processing (ZAP) pilot facility and the EnTranCe energy test site.

Different world

Like green chemistry, microbiology is used to create chemicals, biopolymers and energy carriers. What sets the world of microbiology apart is that it works with living micro-organisms, such as bacteria, enzymes, yeasts and fungi. These are used to convert biomass into useful substances through a biological process, i.e. under mild conditions rather than with high pressures and temperatures or aggressive solvents.

However, Krooneman stressed in her inaugural address that microbiologists cannot operate in isolation. Collaboration with other disciplines is indispensable: “Fermentation or bioconversion alone will not help you. This is because often input streams such as biomass are not manageable for microorganisms. You will have to turn them into bite-sized chunks. Using either physicochemical or biochemical processes, but also process technology, we get those biobased substances into the reactor vessel in a way that allows the micro-organisms to work for us.”

Large volumes

Here, it makes quite a difference whether working at lab scale or in larger volumes. “Scaling-up is a different story in microbiology. It works very differently in large volumes. You will have to face questions like: when do I have collected enough biomass to make the product? How do I get the nutrient into the reactor? And how can I separate, purify and concentrate the substances in the down stream processing stage after fermentation? Again, you will need other disciplines for that. It demands a lot, because you have to understand each other’s language. It doesn’t come naturally. After all, when a microbiologist and a process technologist discuss biomass, they are both talking about something completely different.”

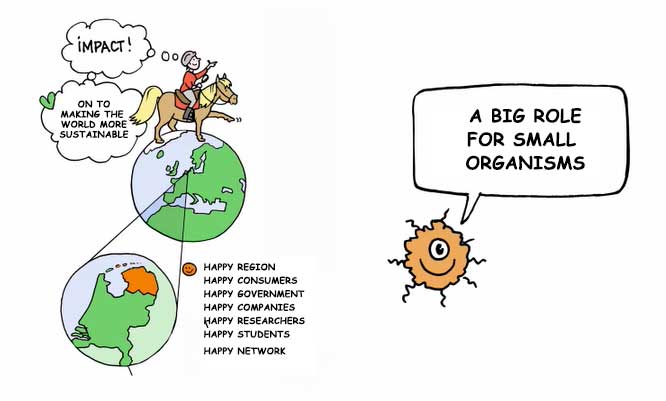

Making a product also ultimately requires people from different backgrounds: from biologists and chemists to environmentalists and process technologists, to economists, AI experts and operators. The RCBBE is the hub between all these specialisms, with the biobased origins of starting materials as the common denominator. This not only involves experts, but also plenty of students. “We make sure they have the right knowledge, are familiar with the phases of the development process and can communicate with different disciplines. So that they are ready to join the business world when they graduate with us.”

Research

Within her professorship, Janneke Krooneman will focus on two lines of research:

- Microbiological manufacturing of biopolymers such as Polyhydroxy alkanoates (PHAs) at laboratory and pilot scale. Research specifically focuses on ways to influence the properties of biopolymers during production, their extraction and purification from the ‘fermentation soup’, and optimising quality and biological end-of-life solutions.

- The production of biogas (CO2 and methane) and hydrogen by fermentation combined with (microbial) electrolysis, among others. This involves the production of energy carriers and possible by-products, which are also interesting as raw materials for the (green) chemical and polymer industry.

“I see a role for myself to really put these small organisms to work,” concludes the brand-new professor. “In doing so, we will make a nice contribution to making the chemical industry more sustainable and can have an impact on education, research and society. Ultimately, this will contribute to a better world.”

Janneke Krooneman’s installation and the preceding symposium (Green chemistry: big role for small organisms) can be viewed on the Hanze University website.

This article was produced in cooperation with Hanze University Groningen.