![]() According to a survey conducted among Bio-based Industry Consortium (BIC) members earlier this year, there are still many questions about digitization and Industry 4.0. During the (virtual) BIC event (“BioSYNERGISE“), representatives from the agri-food, forestry and chemical sectors as well as a brand owners working within bio-based value chains provided insights into activities from their sectors..

According to a survey conducted among Bio-based Industry Consortium (BIC) members earlier this year, there are still many questions about digitization and Industry 4.0. During the (virtual) BIC event (“BioSYNERGISE“), representatives from the agri-food, forestry and chemical sectors as well as a brand owners working within bio-based value chains provided insights into activities from their sectors..

Higher productivity

“Digitization is the key to driving high-tech solutions in agriculture, with which we strive for higher sustainable productivity,” said Ivo Hostens, bioengineer, technical director of the European Agricultural Machinery Industry Association (CEMA) and secretary general of the European Society of Agricultural Engineers (EurAgEng). CEMA represents the interests of 7,000 agricultural machinery manufacturers in Europe and thus 34% of the world’s agricultural machinery production.

“We are involved in a number of EU projects, like NEFERTITI, working with demonstration/ experimentation farms and two EU projects on Digital Innovation Hubs for building digital ecosystems in the areas of digitization and robotics. The main goal of all these activities is to allow easy, secure, transparent data sharing which will benefit the whole production chain. A main bottleneck for data sharing is the lack of trust although there is a willingness to share data. For that reason a code of conduct on data sharing by contractual agreement was developed with all stakeholders within the primary production.”

However, gaining trust is not just about contracting, but also about the correct use of technology. Much of the data that machines collect are already going to the cloud in one way or another, but are not yet linked to each other. “That is why we are developing an open source interface that enables the exchange of data between various systems. Rules in the field of data governance must determine who then has access to the data, under what circumstances and in what way.”

Automatic consent

GDPR, though its principles are not disputed, is a hurdle, according to Hostens, because the regulation requires a 1-on-1 permission for the exchange of data. “We are looking for technical solutions that would still allow an automatic permission, provided certain rules are met. It will be the only way to realize a Common European Data Space: a European infrastructure in which companies can exchange data, both among the different platforms and with governments and administrative entities.”

According to Hostens, it is also important for the future development of AI and robotics’ applications in agriculture that more “open labelled, secured data sets” become available. “We see the importance of IT increasing, not only in the production of machines, but also in agriculture itself. If you really want to be a good farmer, you have to be a good data manager to understand your soils, the status of your crops, to monitor your fleet, etc. We are not there yet. More research is needed into digitization, on data governance, data sovereignty and clear rules for open, secured, labelled data sets.”

Own cloud-based system

In the Finnish forestry industry, data sharing has already gone a long way thanks to digitization and data management, according to the presentation by Jyrki Ovaska, CTO of UPM. UPM is a global forest company (turnover € 10 billion) from Finland with various traditional products, but also innovative ones, such as biochemicals, biomedicals and biocomposites.

“We have 300 to 400 digital initiatives in this company,” explains Ovaska. “We therefore collect a lot of data, from lab data to data on process automation, to inspection reports from suppliers, to weather data to investment and financing data, price data, order tracking and quality monitoring. All our data is available 24/7 all over the world, enabling us to combine, analyse and measure it in various ways, for our partners, forest owners, machine suppliers, technical service providers, but also for operators and production managers in the individual factories. Without our own cloud-based system, the UPM Data Ecosystem wouldn’t even be possible.”

The system is indispensable for managing forest resources, maintaining contacts with individual forest owners, offering digital services and ultimately supplying security. In sales & operations planning, the collection and analysis of all this data also contributes to profitability. “We mainly operate in the B2B market and we have long-term relationships with customers, some of whom have been working with us for decades. As a result, we have historical data, for example on customer behaviour, ordering patterns, etc. that help us to respond to customer needs, optimize stocks, increase customer satisfaction through more accurate delivery and even predict financial results. It enables us to work more efficiently and save costs.”

The UPM Chain of Custody Network uses blockchain technology to track and trace forest biomass, so that UPM can guarantee the use of 100% certified biomass. Chemical company Solvay also uses blockchain technology for traceability, noted Solvay’s Industrial Process Performance & Digital Director, Thierry Cartage. For example, it is utilised in the production of shampoo ingredients and biostimulants from Guar beans. This raw material comes from a large number of smaller farms in India. “If we want to be able to prove sustainability in our chain, we need to register everything from step one, so we need to enable farmers to keep and send records, make print outs, etc.”, he added.

Factory of the future

Digitization has been implemented throughout the Solvay group. “Solvay has made a plan for the factory of the future. The main things we want to achieve is to be more agile and flexible, to produce in a customer-oriented, modular and scalable way, whereby the security of infrastructure and data are important. Everything we do is focused on impact, on time, yields, quality, but also about working conditions.”

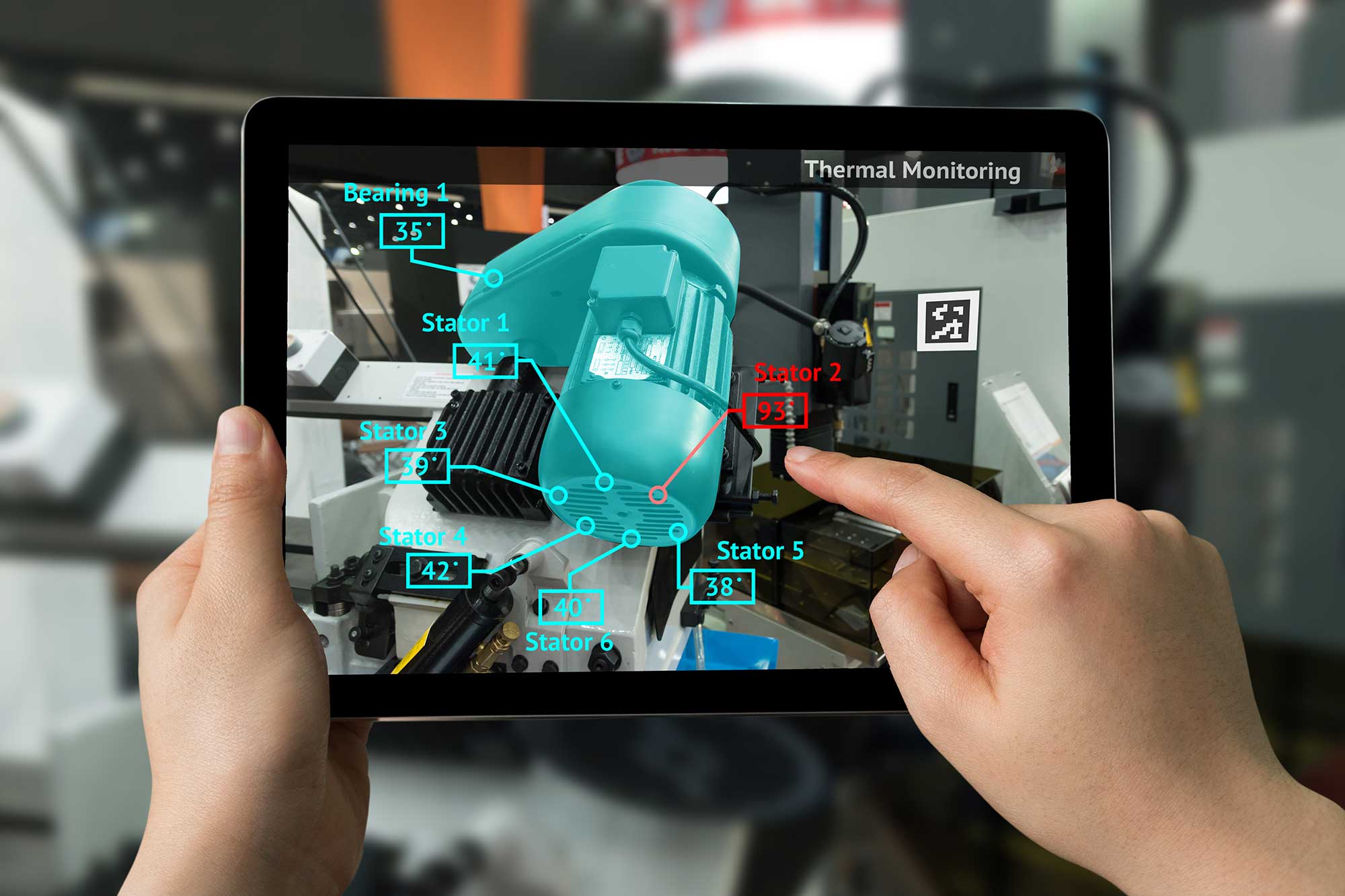

Achieving this requires a digital transformation that is implemented consistently across the company. Setting up a wireless network with sensors that transmits process data from a factory is a relatively simple operation, requiring marginal investments. It can lead to better process performance, more profitability, less maintenance costs and lower fixed costs. But it can also improve human-machine interaction, by streamlining key processes via augmented reality or digital support. Because digitization is not only about computers, it is also a question of training people and optimizing human performance, by giving people direct and indirect feedback on the consequences of their actions.

Cartage: “There is also a social component: the ‘mindset’ or attitude and behaviour of employees must be transformed. Not only data scientists but also technicians and bioengineers must understand what data is and what role it plays in our production process. Collaboration in multidisciplinary teams is a key to success.”

Consumer confidence

Ultimately, in the consumer market, transparency, traceability and sustainability are crucial to gaining end-consumer confidence. “Data is our new b(e)acon,” said Kurt Lermann, Global IT Service Leader at Procter & Gamble. The company has thousands of brands in various consumer sectors: from toilet paper to razors, to shampoo, cleaning and health products.

The production processes, but also the supply chains, are therefore very different. “Often, the raw materials come from agricultural products, so if we want to send data to consumers and governments, we need to know who we bought which product from, how it was produced and how it gets from the farmer via suppliers to our plants.”

The factories are equipped with Industrial Internet of Things sensors that, for example, keep track of how much water or electricity is consumed in the various production processes. Via P&G’s own “Quantum” system, this detailed information can be viewed, at the level of a country, a business unit or an individual production unit. “This also helps us to make immediate adjustments if there are noticeable deviations at a location.”

Even after the factory, P&G continues to monitor its products. “We also look downstream at our clients, distributors and ultimately the store. Data, across end-to-end supply chains, keeps it all together. ”

The presentations show that digitization is a very broad concept. It affects all aspects of all businesses. It means that there is a growing need for the bio-based industries to deal with digitization and Industry 4.0 in the future. Dirk Carrez, BIC Executive Director, summed it up: “As bio-based industries, we are all part of much wider value chains. This means that we must enable interconnections and collaborations with other sectors. Digitization is part of this, which is why it will also be an important focal point of the upcoming Circular Bio-based Europe public-private partnership and the new Strategic Innovation and Research Agenda (SIRA).”

This article was written in collaboration with the Bio-Based Industries Consortium.

Image above: HQuality/Shutterstock