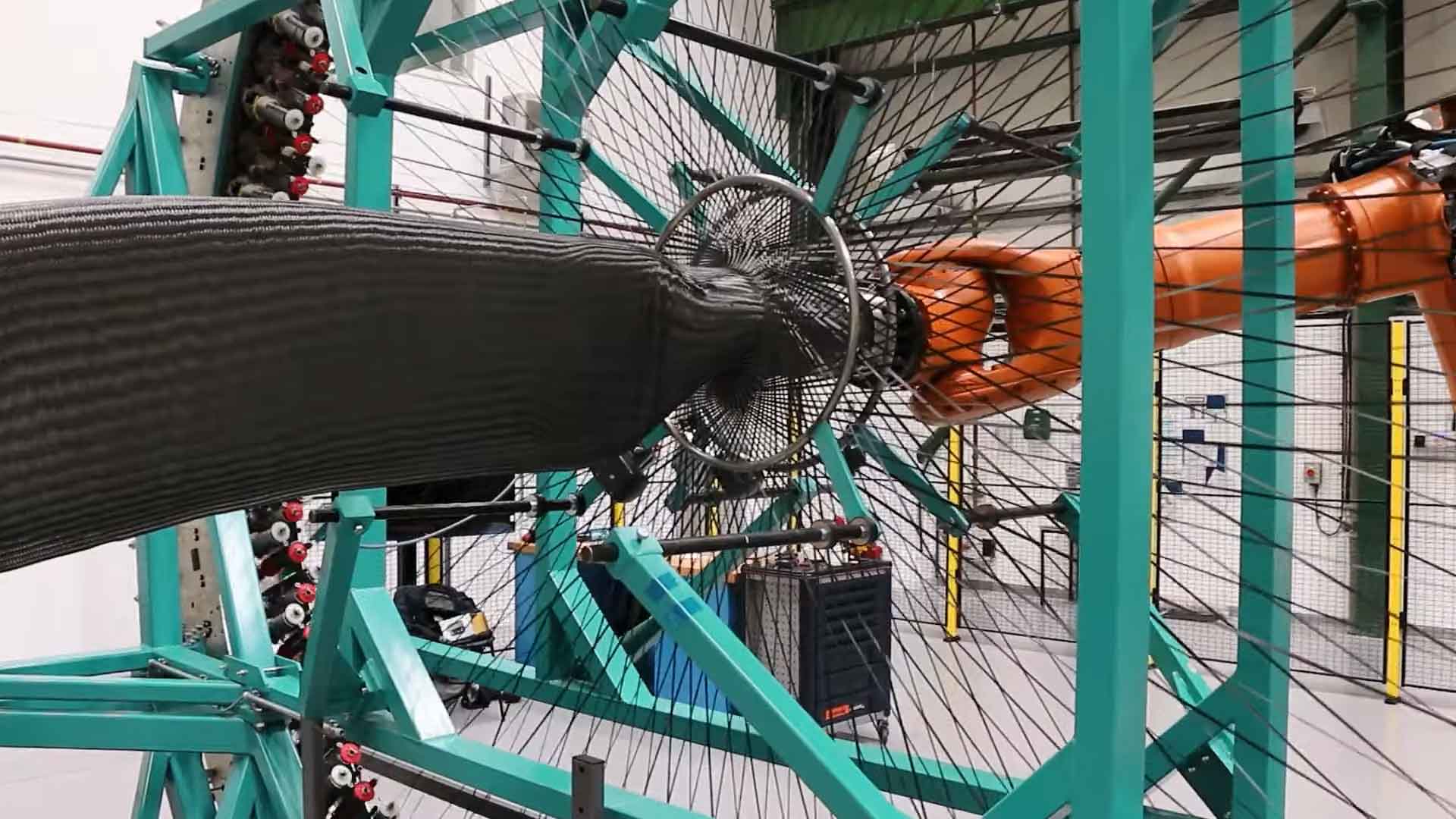

Together with energy companies, research institutions and the Flemish textile company Concordia from Waregem, ACT developed lightweight rotor blades for wind turbines. They consist of a composite frame covered with technical fabric. The pre-stressed, textile-covered rotor blades are 30% cheaper to make than conventional blades, while the production process uses almost 7% less energy. They have a shape that can be actively changed to control loads. The fabric can be easily recovered and reused once the blades have been disassembled at the end of their life. Recycling of conventional rotor blades is still problematic.

Moreover, because the blades are 24% lighter, they could be made longer at the same weight. This increases the yield of the turbine by 9%, without further modifications. A first prototype rotor blade was successfully tested in Scotland last summer.

See the video for more information.

Image: Offshore Renewable Energy Catapult/YouTube