Project partner Luleå University of Technology (LTU) focused on the first process step of

capturing and concentrating CO2 from industrial point sources. Their team developed a hybrid

chemo-enzymatic process consisting of a novel solvent blend and an ultrastable carbonic

anhydrase (CA) enzyme. The 3-component CO2 capture process was scaled up in a pilot rig, and the set-up further used for real off gas pre-treatment in the project.

The biotechnological conversion of (captured) CO2 and the co-substrate hydrogen by

microorganisms poses technical and economic challenges because it takes place in the liquid

phase and the substrates are gases which are poorly soluble. The BioRECO2VER project

investigated two approaches to address this: pressurized fermentation and bioelectrochemistry.

Fermenter

Project coordinator VITO designed a flexible and multifunctional high-pressure fermenter, customized for research activities with advanced online sensors, monitoring and control, and also including a membrane filtration unit to achieve high concentrations of the microbial biocatalysts. The set-up was broadly tested in the BioRECO2VER project both with pure CO2 and CO2-rich off-gases but can also be used for investigations involving other poorly soluble gases, such as methane, oxygen, or synthesis gas. Pressures up to 10 bar can be applied.

Bio-electrochemical platform

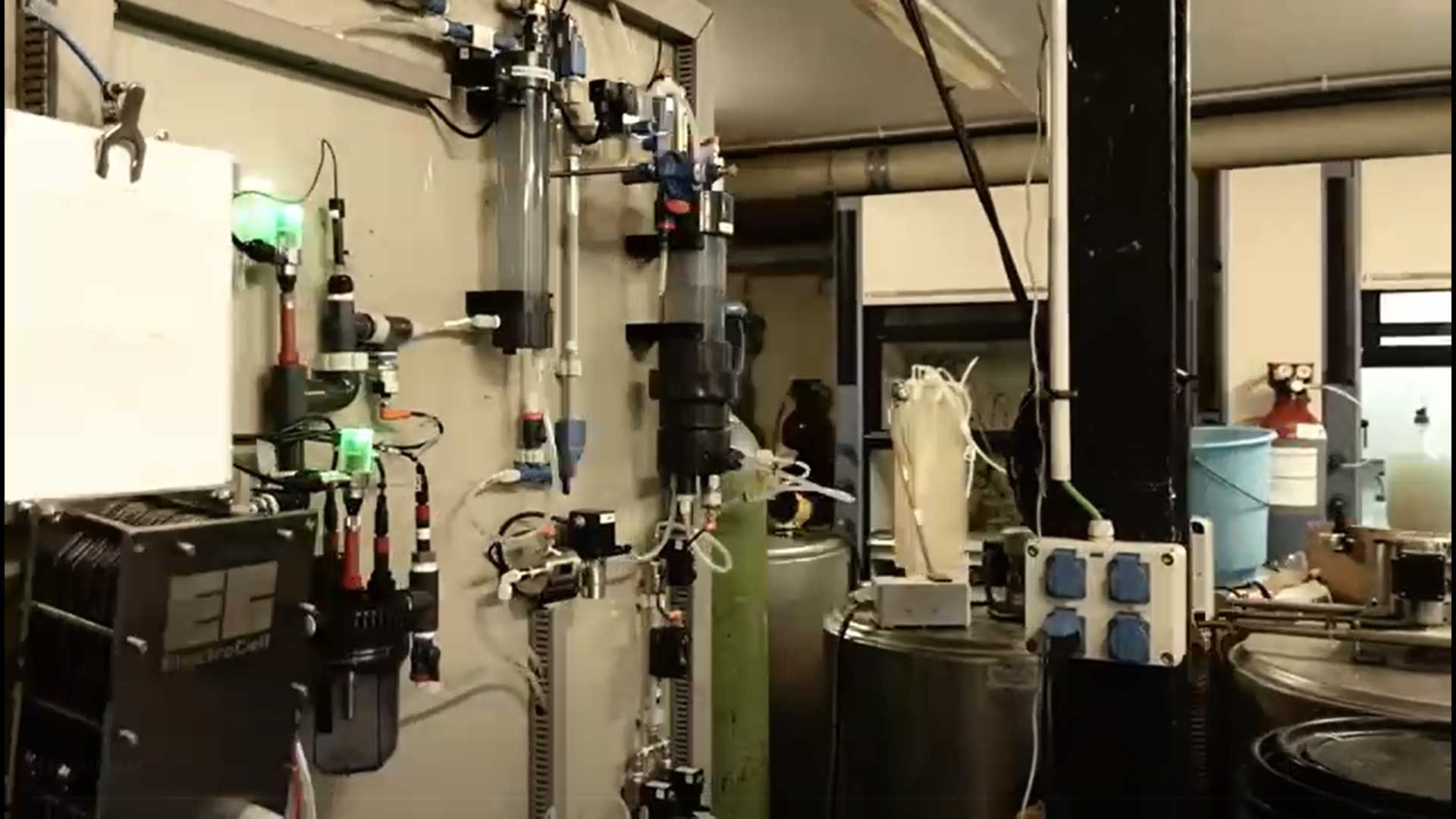

University of Girona designed and tested a bio-electrochemical platform that is unique in the

world. The key differentiators of the pilot plant are:

- Two parallel lines to test engineered strains and bio-electrochemical systems;

- Fully automated pilot plant capable to control key operational parameters (pCO2, pO2, pH2, pH, Temperature) to intensify the process performance;

- Solid-liquid separation unit (membrane) to recover the planktonic cells and return them

- into the bio-electrochemical systems.

This unique infrastructure will be used beyond the project to support further research and

development activities in the broad area of CO2 capture and conversion.

Presentations

Last November, the consortium shared the highlights of the project and additional results in a webinar with a wide and international audience. All presentations are freely accessible here.

The BioRECO2VER project received funding from the European Union’s Horizon 2020 programme for research and innovation.

Image: University of Girona