BioBTX is developing the ICCP (Integrated Cascading Catalytic Pyrolysis) technology for the cost competitive production of drop-in sustainable aromatic chemical intermediates, like Benzene, Toluene, Xylenes (BTX). These are cornerstone chemicals for the production of plastics.

The technology is highly flexible with regards to feedstock materials, including non-food liquid and solid biomass as well as end-of-life materials. By using renewable carbon sources, a significant contribution to the circular economy will be made, reducing the use of fossil feedstocks and lowering emission of greenhouse gases.

The new pilot plant will initially convert non-food liquid biomass, like glycerol and fatty acids. In a second stage, the unit will be made suited to process solid biomass and end-of-life materials, like plastics and composites as well.

Relocation

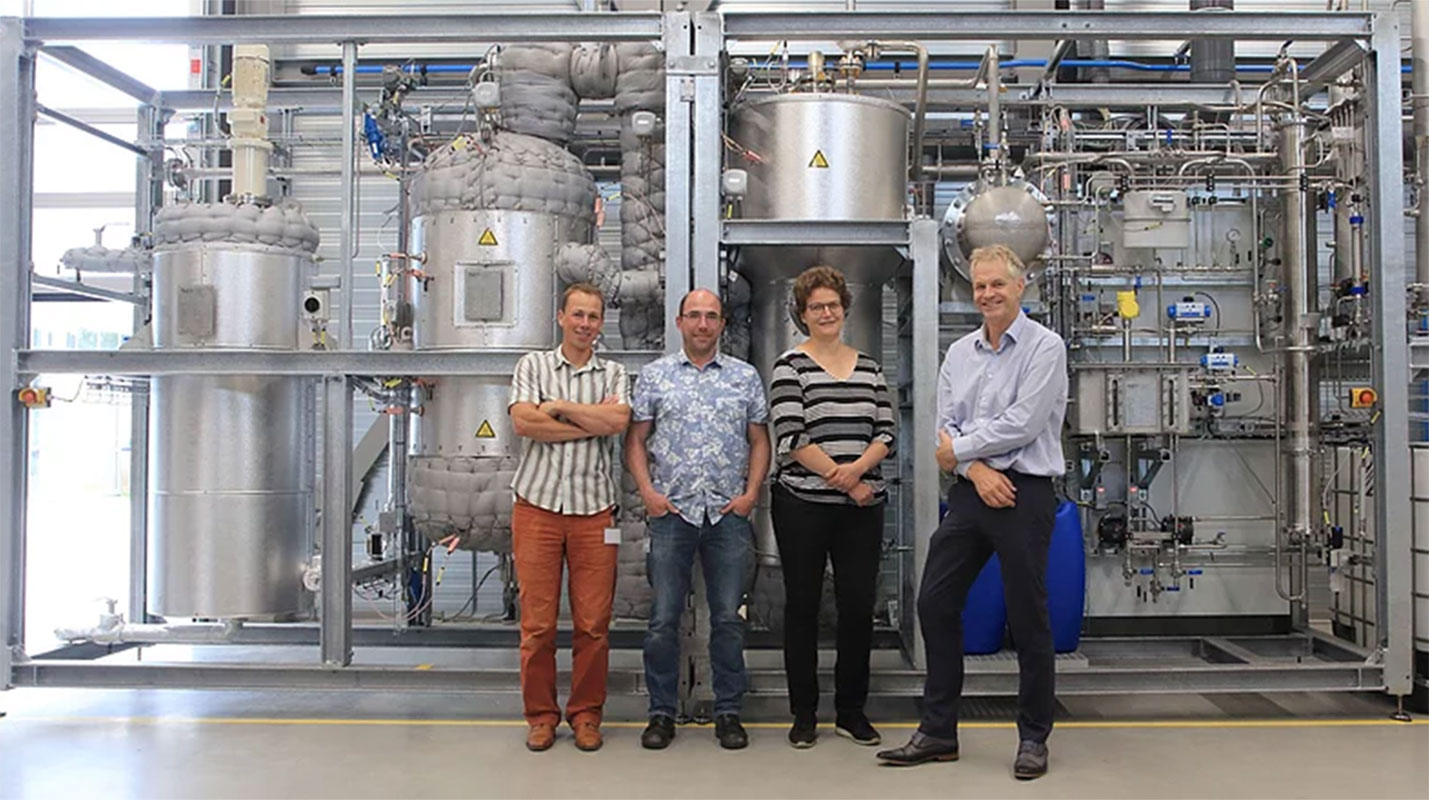

The pilot plant is located at the Zernike Advance Processing (“ZAP”) site in Groningen, a semi-industrial environment with a focus on biobased products. At ZAP, knowledge institutions and businesses can take the important step from lab bench to medium scale production in green chemistry and biotechnology. Earlier this year, the offices of BioBTX have relocated to this site, thus facilitating optimal communication and operation.

‘We are excited that we can make this next step in commercialization of our technology following successful laboratory experiments in collaboration with the University of Groningen’, Pieter Imhof, CEO of BioBTX says. ‘This is a milestone in our work to support the transition to a sustainable and circular economy. With this pilot plant we will be able to proof and optimize the technology, and provide samples to our partners for product and application research, for example by conversion into biobased plastics.’ The scale up is supported by shareholders as well national, regional and European subsidies. Among these are RVO, SNN, Provinces of Groningen and Drenthe and the municipality of Emmen.