Two start-ups registered immediately after iLab’s foundation: Bionative Industries, which manufactures water-soluble plastic substitutes from starch, and Designer Don Kwaning, who develops packing and construction materials from the soft rush plant.

Prolific weed

Don Kwaning, who studied at the Design Academy in Eindhoven, accidentally discovered the soft rush plant in the Province of Drenthe. The National Forest Service in the Netherlands (SBB) has its hands full with this prolific weed. Kwaning took the plant apart and discovered that it can be used to make several materials: ‘The fibres can be used to make paper and textiles. The pith inside the stem can be blended and compressed into a kind of polystyrene foam. Under high pressure, it can even be compressed into construction plate, comparable to MDF, but then without a binding agent.’

The Province of Noord-Brabant drew Kwaning’s attention to the iLab, and he is currently in the process of writing a business plan. ‘I was trained in the creative arts. Setting up a company requires a different way of thinking that I am not accustomed to. I am therefore looking for help with the business side of entrepreneurship.’

Roaming

This is exactly where iLab can be of assistance. Project Manager Geert Mol of the Green Chemistry Campus: ‘We often see young companies roaming the prize circuit and getting a great deal of media attention, but they are not capable of developing themselves commercially. This is unfortunate. This is why we support them across the full breadth of business operations: with low-threshold accommodations and laboratory facilities, sources of financing, guidance and support by people with technical competencies, as well as coaching in the field of entrepreneurship. Furthermore, in the Delta region we have access to an extensive ecosystem, a relevant network of companies, government organisations and knowledge institutions ranging from senior secondary vocational education institutions to universities.’

This support is an important factor for Bionative Industries as well. Bart de Raad, student of Chemical Technology at Avans University of Applied Sciences, founded this company last year together with his partner Daan Sybesma. The biodegradable plastics substitute they are developing is especially well suited for single-use plastics that do not come into contact with moisture. ‘An example that comes to mind is bread clips: tiny devises that everyone immediately discards. It seems insignificant, but this product is used on a gigantic scale throughout the world, and therefore has a big environmental impact.’

Originally, De Raad manufactured the material in his garage at home. But he has since moved his lab to a business centre in Breda. However, De Raad also required support at a business level. When he heard about iLab from a fellow student, he immediately contacted iLab. ‘We are still in the technical development phase, but in the near future we will have to get together with a customer and negotiate a contract. This can have a significant impact on your future. So it is comforting to know that we are backed up by a team of experts that can advise us.’

There is still plenty of room for other start-ups in the iLab. For more information, please contact Project Manager Geert Mol.

This article was created in cooperation with Circular Biobased Delta.

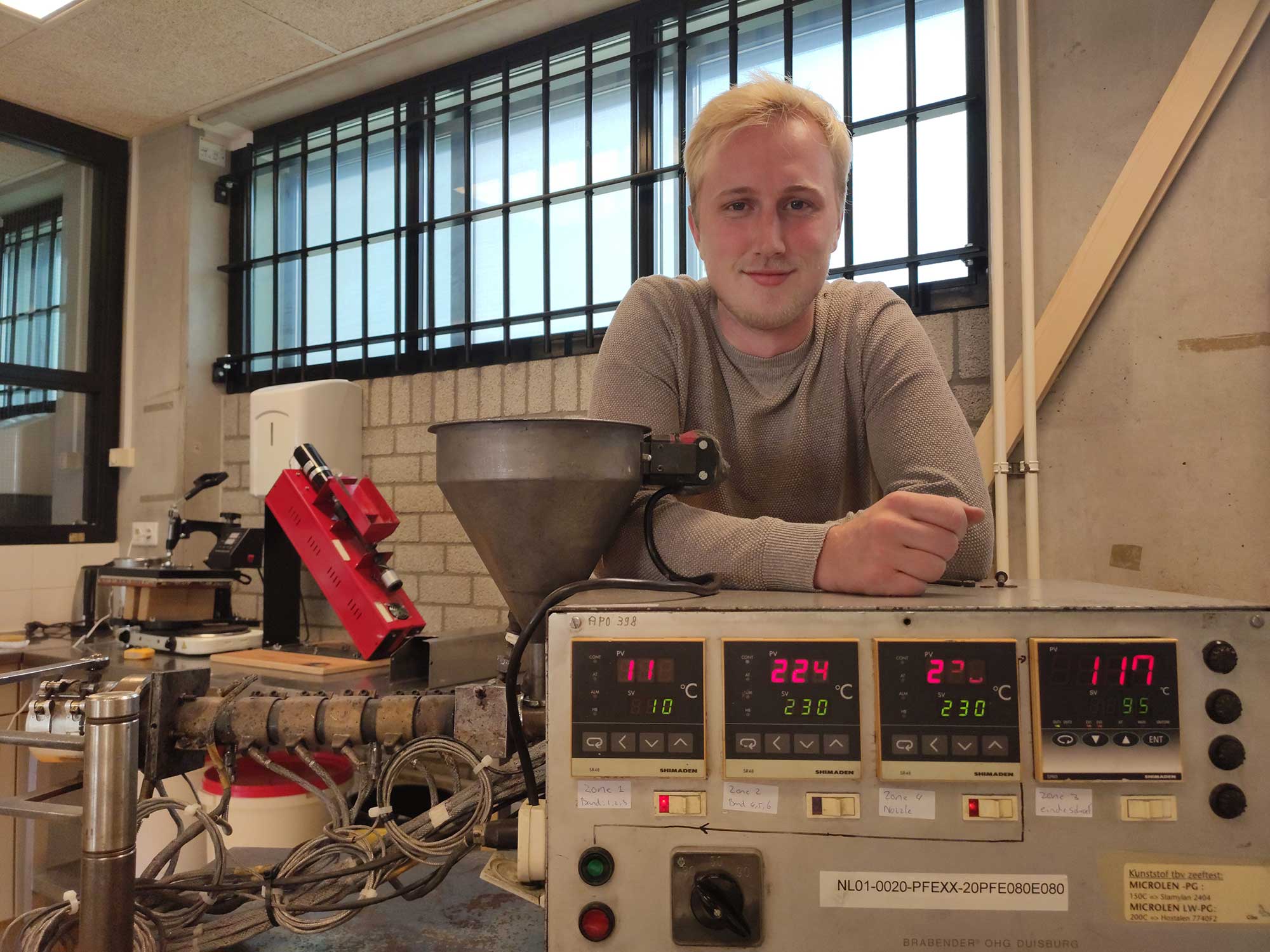

Image above: Don Kwaning