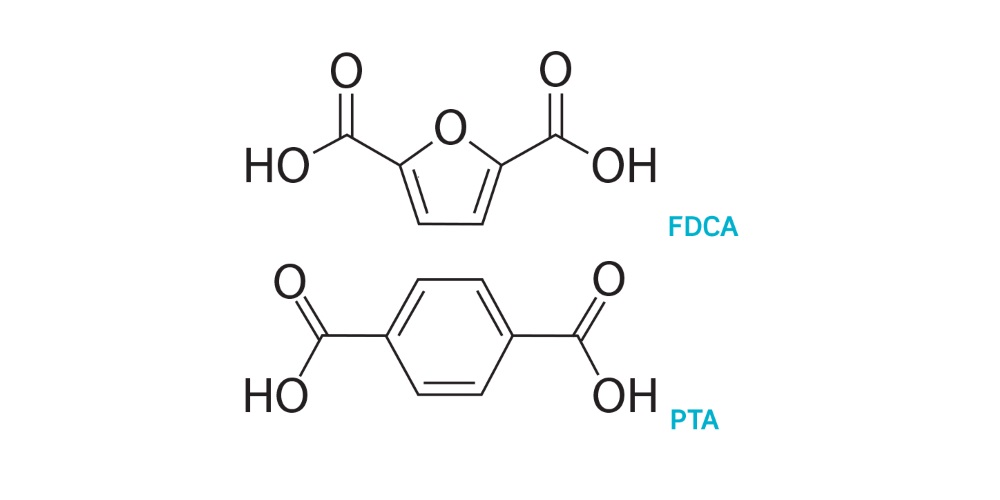

In his presentation Wery examined Corbion’s research of the past three years in more detail. The route developed by the company is based on C6 sugars (fructose) which are taken via HMF to FDCA. The FDCA is then purified so it can be used for bioplastics such as PEF.

According to Wery, the first step especially was challenging. ‘HMF is unstable. All kinds of undesirable by-products can arise during the process, like humins. That in turn leads to a tarry end product. In the end we were able to ‘tweak’ the process to produce a crude HMF with a purity level which is sufficient for FDCA.’

High selectivity

In Corbion’s process, the HMF can remain relatively crude because of the next step, in which it is converted to FDCA via biocatalysis with specially developed microorganisms. The selectivity in this case is extremely high: 99+% is converted into FDCA.

Wery stated that the process was scaled up in the past years to pilot level. A toll manufacturer has since produced several tonnes of HMF via the process developed at Corbion. At the Bioprocess Facility in Delft, hundreds of kilograms of FDCA have since been produced based on this HMF. ‘We performed application research at the same time, focusing on bottles and foils.’

Advantages of a ‘bio route’

Apart from the end products, Corbion still has to do the necessary work to optimise the process further. The design of a process on a commercial scale is already receiving attention as well, in which aspects such as heat transfer (especially in the conversion of HMF to FDCA), oxygen transfer during the fermentation and fluid dynamics are also examined.

‘We are working very well on this level together with Delft University of Technology, and the lights are still green,’ according to Wery. ‘We are getting closer to a commercially viable process. For example, we have lowered the overall sugar input and raised the titers. Further process optimisation measures, as explained, are required.’

As is known, other parties, such as Synvina and ADM/Dupont, are also working on FDCA and bioplastics based on FDCA. Wery stated that there is space for several providers, although probably the best technology will win. ‘We specifically see advantages in the bio route from HMF to FDCA. As explained, it is a highly selective process under relatively mild conditions, which gives us high yields and fewer unwanted by-products. And furthermore, it is enough to use crude HMF, which keeps the process costs down.’