Maastricht University, RWTH Aachen and the Fraunhofer IME work together in the international, multidisciplinary AMIBM institute with support from the Province of Limburg. ‘AMIBM is living proof that cross-border cooperation works in Limburg,’ stated the new Limburg member of the Provincial Executive Joost van den Akker (Economy and Knowledge Infrastructure) at the opening of the third ABC Conference on Friday 20 April at Brightlands Chemelot Campus in Geleen.

The multidisciplinary approach was well reflected in the packed conference programme. It started with the keynote speech on microrobotics (see the news item on this) by Professor Pasi Kallio from Tampere University of Technology in Finland. 20 speakers from six areas of expertise then followed each other in rapid succession. In between, Maastricht University students competed with their poster presentations for the Best Poster Award 2018. Despite the diversity of the talks, the recurrent theme was the fact that issues are tackled from a number of scientific disciplines. That is the essence and is how AMIBM ties in with the Brightlands motto: knowledge crossing borders.

Natural materials

Professor Rainer Fischer of the AMIBM introduced the first session, which focused on the use of natural materials for technological applications. For example, Professor Udo Conrad of the Leibniz Institute of Plant Genetics and Crop Plant Research (IPK) is studying how (tobacco) plants can make fibres that are similar to those occurring in spider silk. Spiders are able to build webs of thread with high elasticity very efficiently, using them catch their prey without the web breaking. Conrad envisages applications of fibres with these properties to construct elastic ‘scaffolds’, support structures for cultivating human organ tissue.

Dr Luisa Bortesi is involved in this research through the AMIBM. She is investigating how it is possible ‘to make plants behave like spiders, by making the DNA resemble them.’ Purification of the fibres still forms a challenge, as does preventing the human body from rejecting biomaterials created this way. In addition to medical applications, Bortesi also sees other possibilities, such as cultivating elastic wood.

New building blocks

Professor Stefaan de Wildeman of the AMIBM believes there is a great need for new biobased building blocks, chemical building blocks with unique properties, as an alternative to the ‘fossil’ chemistry. Dr Martin Schürmann from InnoSyn (originating from DSM) is one of the people working on this. The company is currently building a pilot plant for biocatalysis at Chemelot, which should open around mid-2018. Biocatalysis is the use of enzymes as catalysts for organic chemistry, which integrates biology and chemistry. This is a means of developing new, more effective routes for the production of chemicals.

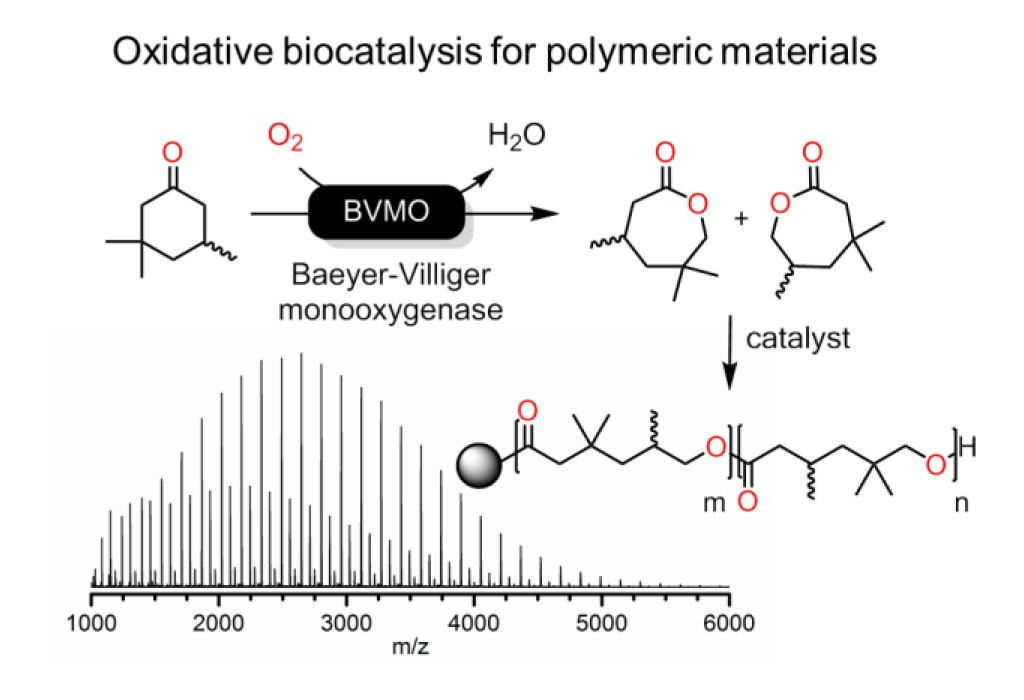

Dr Marie Delgove (AMIBM) looked in more depth at the research into one of these biocatalytic processes in the Horizon 2020 Robox project.

Performance materials

The high performance biobased materials theme was introduced by Professor Sanjay Rastogi. This concerns materials which can cope with high loads, such as biocomposite. Dr Guy Buyle from Centexbel provided an explanation of the BIO4SELF project, which is investigating the possibilities of making a self-reinforced biocomposite (SRPC) from PLA. This means that both the fibre and the matrix are made from the same material, although each has different properties. The advantage of self-reinforced materials is that they are lightweight and easy to recycle. Some research is still required into improving the sturdiness of PLA. Buyle sees possibilities for these materials to be applied in the automotive and white goods industries, as well as for sports equipment.

Dr Jules Harings then gave an inspired presentation on the hydrogen bond in polyamides.

Sustainability

The biobased origin of materials does not mean that these materials themselves are automatically sustainable. That was the topic of the fourth session, introduced by Dr Yvonne van der Meer (AMIBM). A live connection was set up for this section with Professor Claude Villeneuve from the Université du Quebec au Chicoutimi (Canada), who could not attend for personal reasons. Villeneuve has put together a model with six dimensions to measure the sustainability of materials. Ecology is only one of these dimensions; social, economic, ethical and cultural factors also play a part. According to this method, a paperback book printed on new paper could be more sustainable than one printed on recycled paper. This is because recycling requires an extensive logistics operation and processing steps that impact the sustainability negatively.

Dr Achille Laurent (AMIBM) dealt with the effect of the supply chain in more depth. He made LCA analyses of laminated wooden beams from Canada, which showed that the greatest impact on the level of sustainability of a product is determined by the means of transport (by road or by water).

Textile applications

Professor Gunnar Seide of the AMIBM introduced the topic of textile: it is pliable, elastic, breathes and has many other properties that make it the ideal material for many applications, from carpets to clothing and fibre mats for reinforcing composite. According to Professor Thomas Gries from the Institute for Textile Technology Aachen (RWTH-ITA), the area of research has grown enormously. Not only because there are numerous starting materials (natural and synthetic), but also because there are at least 20 processing methods for each material, many ways of turning fibres into yarns, just as many ways of processing these yarns into textiles and then countless applications of these textiles. It is not surprising that ITA is involved in dozens of research projects, together with partners from the industry.

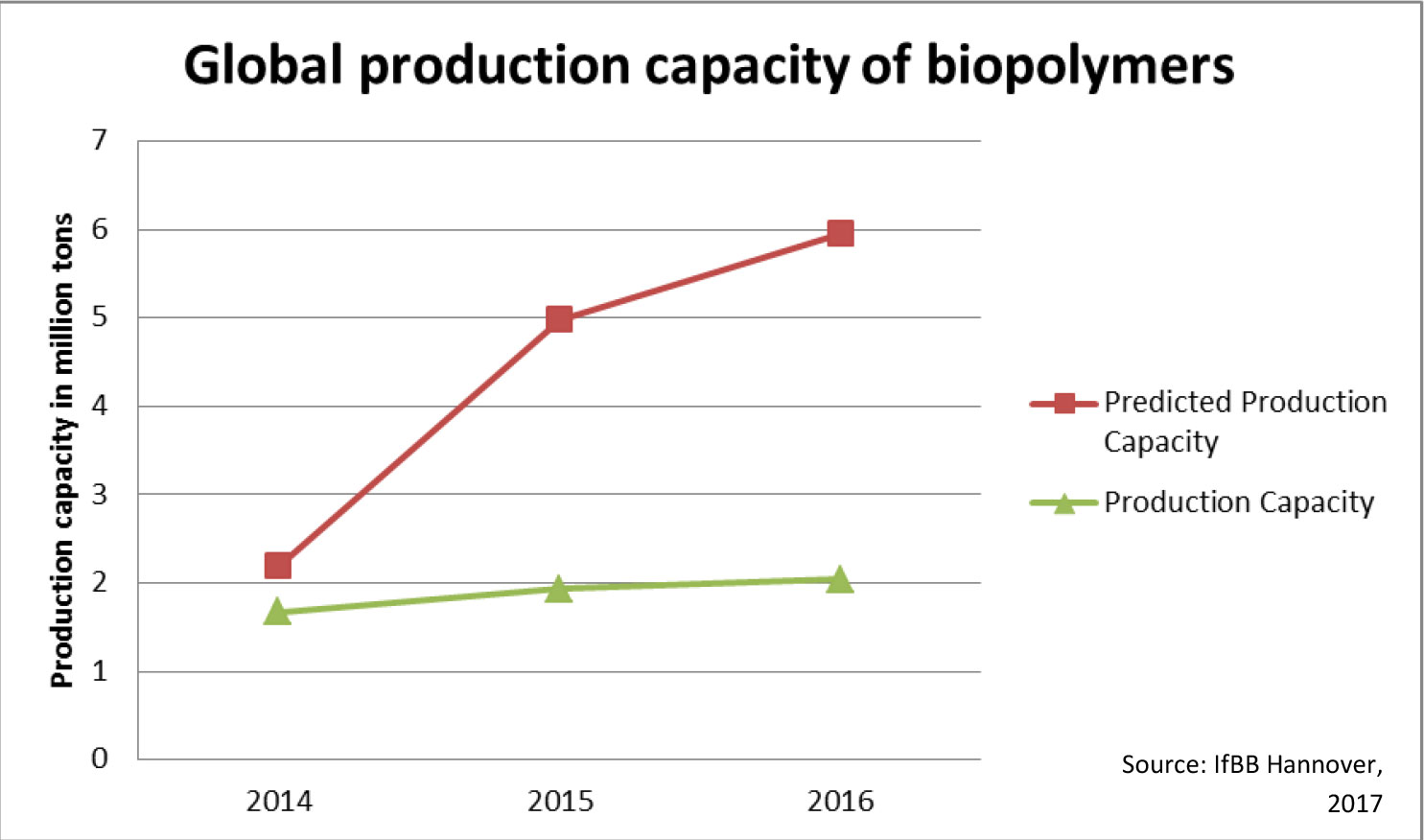

Dr Marga Merke (AMIBM) discussed the market opportunities for biobased textile applications. In her opinion, the global market for biopolymers can be tripled to 6 Mtonnes annually. To achieve this, the ‘blue ocean strategy’ would be the appropriate way; don’t try to compete with others on an existing market, but create your own, new market. According to Merke, it is about becoming the ‘Starbucks of the biopolymer market’. Starbucks may not have been the very first coffee bar, but it was the first one to construct a unique experience around it.

Medical scaffolds

Biobased materials, and especially biodegradable materials, can be attractive for the medical world if they are non-toxic and biodegradable. This is the area of expertise of Professor Stefan Jockenhövel of the AMIBM, who introduced this last session. Dr Lorenzo Moroni (MERLN Institute for Technology-Inspired Regenerative Medicine) discussed the techniques for building ‘scaffolds’ from biobased materials with the appropriate pore structure and any desired shape, for example for regenerating an ear or a nose. The challenge is that the scaffolds need to have the mechanical strength of the original material (such as cartilage) but still be biodegradable. Besides using 3D printing to create scaffolds, electrospinning can be used to attach a random or locally densified structure to the body part to be restored, on which stem cells can form a tissue. This can be bone, for instance, but also heart tissue.

Dr Anne Coenen (AMIBM) discussed the regeneration of heart valves in more depth. They consist naturally of elastin and collagen (cartilage). That makes them strong, but also flexible. Heart valves that have been regenerated using scaffolds, however, are often stiffer than the original valve. To prevent this, a scaffold is needed which also has a certain elasticity itself. Imitating elastin through a combination of polymers and proteins is a way of achieving this. The result of this hybrid solution is an adaptable, biocompatible, elastic material for engineering heart valve tissue.

Last ABC Conference

The ABC Conference 2018 in Chemelot was the last of this kind. Three years after its inception, the event is to be scrapped. At least, in its independent form. As of next year, the ABC Conference will be combined with the Brightlands Rolduc Polymer Conference 2019 in Kerkrade, on 9 to 11 September 2019.